One of the key advantages of the Tumbler Vibrating Sieve is its low maintenance cost, making it a cost-effective and long-lasting screening solution. The design prioritizes durability and minimal wear, significantly reducing the need for frequent replacements and maintenance interventions.

Minimal Wear & Easy Maintenance

The Tumbler Vibrating Sieve is engineered for long-term reliability, with only a few easily replaceable wear components:

✔ Screen Mesh – The primary wear component, securely fastened using special adhesives or welding to ensure maximum tension and durability.

✔ Sealing Rings – Prevent leakage and maintain consistent screening efficiency.

✔ Rubber Balls or Brushes – Used in the self-cleaning systems to prevent clogging and ensure smooth operation.

With low acceleration forces and gentle motion, the sieve dramatically extends the lifespan of the screen mesh and other wear parts, reducing replacement frequency and operational costs.

Durability Enhanced by Drum Principle

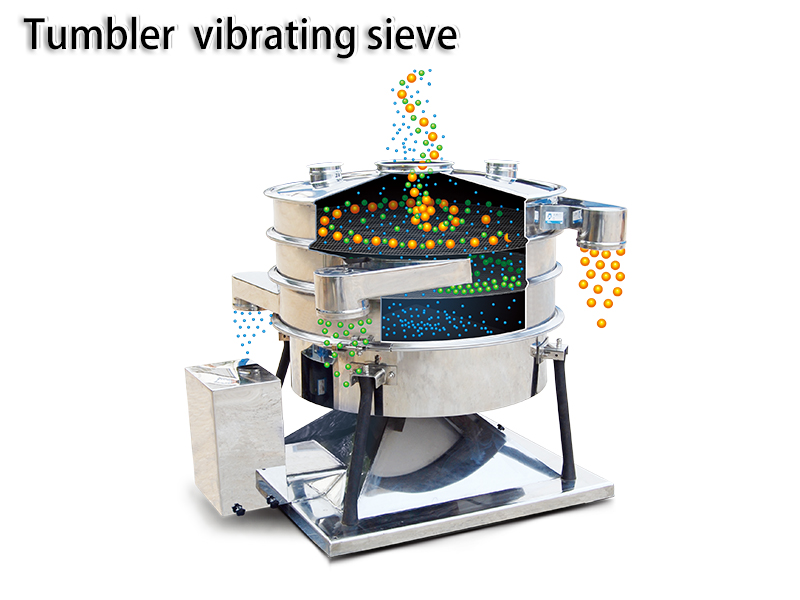

The Tumbler Vibrating Sieve is designed based on the drum principle, ensuring:

✔ Tightly stretched screen mesh – Prevents sagging or tearing, improving screening efficiency.

✔ Lower mechanical stress – The sieve operates at low acceleration and reduced impact force, significantly prolonging mesh and component lifespan.

This innovative design ensures smoother screening, reduced downtime, and enhanced overall efficiency.

Negligible Dynamic Load & Stable Operation

Unlike conventional vibrating screens that generate high dynamic loads, the Tumbler Vibrating Sieve is uniquely designed to have negligible dynamic impact on its surroundings.

✔ Factory Pre-Balanced for Stability – Before shipping, each sieve is precision-balanced using specialized equipment to ensure perfect equilibrium.

✔ Ideal for High Steel Structures – Due to its low dynamic load, the sieve can be installed on high steel structures without causing excessive vibrations.

✔ On-Site Fine-Tuning – To accommodate site-specific conditions, a final balancing adjustment is recommended before startup.

This guarantees smooth, stable, and vibration-free operation, making it suitable for sensitive environments where structural integrity and operational safety are priorities.

Key Advantages of the Tumbler Vibrating Sieve

✅ Minimal Wear Components – Only screens, seals, and cleaning accessories need periodic replacement.

✅ Extended Mesh Lifespan – Gentle acceleration and tensioning techniques prevent premature wear.

✅ Factory-Calibrated for Stability – Ensures smooth, vibration-free operation upon installation.

✅ Low Dynamic Load – Can be placed on high steel structures without structural concerns.

✅ Reduced Maintenance Costs – Long-lasting components lower overall operating expenses.