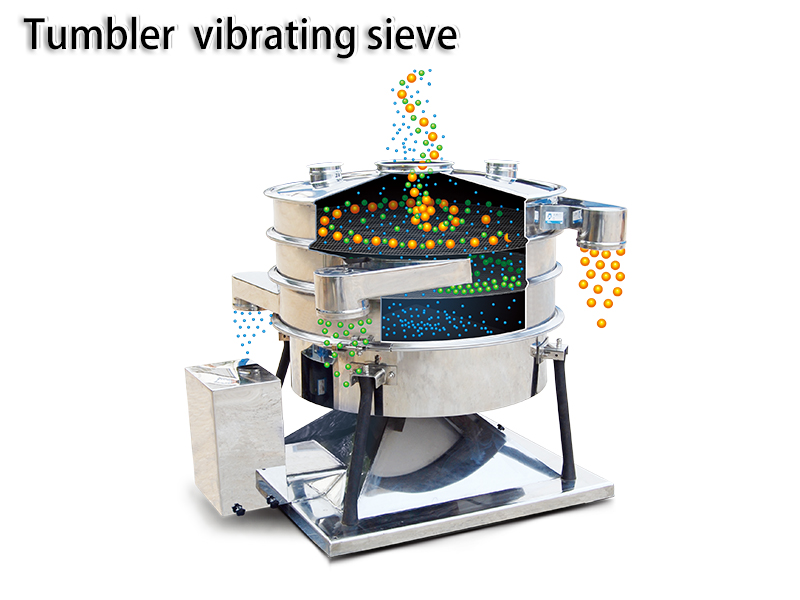

The Tumbler Vibrating Sieve: A Revolutionary Solution for Continuous, High-Performance Operations

In the world of industrial machinery, efficiency and reliability are paramount. One of the key innovations that has significantly enhanced operational productivity is the Tumbler Vibrating Sieve. Designed for high-performance operations, this equipment offers an exceptional solution to reduce maintenance downtime and ensure continuous, uninterrupted production.

Reduced Maintenance Time and Effort

A standout feature of the Tumbler Vibrating Sieve is its incredibly efficient maintenance system. The equipment has been designed with simplicity and speed in mind. Maintenance tasks, such as disassembly and installation, can be completed in as little as 15 minutes, making it one of the most time-efficient machines in its class. This quick turnaround reduces the need for extended downtimes, ensuring that operations remain on schedule without delays.

Moreover, the machine’s design minimizes the need for repeated bearing lubrication. Traditional equipment often requires frequent bearing maintenance, leading to higher operational costs and downtime. In contrast, the Tumbler Vibrating Sieve reduces these maintenance requirements, making it an ideal choice for industries where time is money.

Continuous Operation with Maximum Efficiency

The Tumbler Vibrating Sieve is engineered to ensure 24/7 continuous operation without compromising on performance. This robust system can handle full-load operations around the clock, enabling industries to maximize production capacity without the constant need for maintenance. The machinery is designed to withstand demanding operational environments, ensuring reliability and durability throughout its lifecycle.

Dust and Pollution Control for Cleaner Operations

Another key advantage of the Tumbler Vibrating Sieve is its innovative dust and pollution control system. Unlike traditional machinery that requires additional air purification or dust collection systems, the Tumbler Vibrating Sieve has been built to operate efficiently without these extra components. The equipment is equipped with a unique dust-proof design, which works in tandem with existing ventilation systems in the facility, significantly reducing the amount of dust in the environment.

This self-sufficient dust management system ensures that the equipment operates cleanly, reducing the need for extra maintenance or investment in supplementary air purification systems. With these built-in features, businesses can focus on optimizing production without worrying about the added cost of specialized air filtration or dust collection devices.

Innovative Design Features for Enhanced Performance

The Tumbler Vibrating Sieve goes beyond traditional equipment designs by incorporating airtight and vacuum features into its system. These advanced design elements enhance the machine’s operational performance by providing better material processing and minimizing the risk of contamination. The sieve also includes chloride purification technology, offering an additional layer of protection to ensure that the processed materials meet high-quality standards.

This airtight and vacuum design not only enhances the overall efficiency of the sieve but also helps maintain the integrity of the materials being processed. Whether handling delicate or sensitive substances, the Tumbler Vibrating Sieve ensures that the process is carried out with the utmost precision, providing superior results each time.