In industries that require high-performance screening of diverse materials, swing screens have emerged as a unique and effective solution. This low-frequency vibrating screen, which mimics manual shaking, offers a distinct advantage over conventional high-frequency vibratory screens. Designed to efficiently process materials with a variety of shapes, including round, cylindrical, and flaky types, the swing screen is ideal for precise screening and materials that are prone to mesh blockages. By replicating the manual shaking process, swing screens ensure optimal separation with minimal risk of clogging, making them indispensable in several industries, from chemicals to food processing.

Principle of Operation: Low-Frequency Shaking for Effective Screening

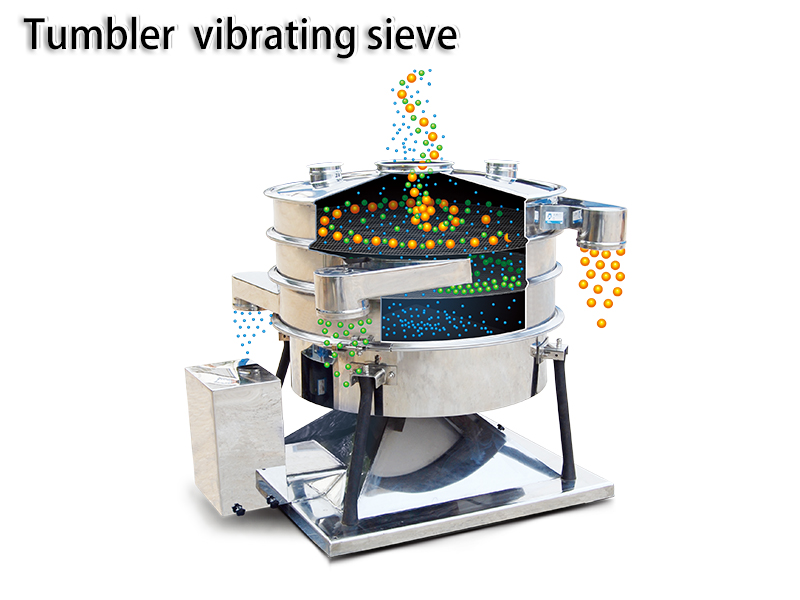

The swing screen operates based on a unique working principle that combines radial displacement and circular motion to create a non-linear three-dimensional movement. This movement mimics the natural shaking motion of the human hand, which is highly effective in separating materials with a variety of shapes and sizes. The working mechanism can be explained as follows:

- Instantaneous Movement: The material on the screen experiences radial displacement and combines with a circular motion around the displacement axis, forming a spiral motion. This two-in-one motion is crucial for achieving efficient separation.

- Adjustable Eccentricity: The eccentric vibrator can be adjusted to change the eccentric distance, which in turn adjusts the amplitude and intensity of the movement. This makes it versatile enough to accommodate different types of materials, from fine powders to coarse particles.

- Simulated Manual Shaking: The combination of radial displacement and circular motion produces a motion similar to manual hand shaking, effectively preventing the clogging of mesh and providing gentle handling of materials that would otherwise be difficult to screen.

Material Movement on the Swing Screen

The motion generated by the swing screen ensures that the material is thoroughly dispersed and evenly distributed across the screen surface, maximizing the chances of separation. The movement allows materials to slide and shake without being subjected to harsh vibrations, which is particularly beneficial for fragile or easily broken materials. As the material moves along the screen, it is gradually filtered into different grades based on its size.

Key Advantages of Swing Screens

1. Precision Screening of Complex Materials

One of the main advantages of the swing screen is its ability to handle materials of varying shapes, including round, cylindrical, flaky, and irregularly shaped particles. These types of materials are often challenging for traditional vibratory screens, which struggle with blockages and uneven material distribution.

- Ideal for Irregular Materials: The gentle, spiraling motion allows these materials to move across the screen surface without accumulating or forming clumps, ensuring a more efficient screening process.

2. Preventing Mesh Blockages

Materials that tend to clog screens, such as powders and sticky substances, benefit greatly from the swing screen's unique motion. The combined radial and circular motion minimizes the risk of material buildup on the mesh.

- Reduced Clogging: The simulation of hand-like shaking helps in preventing the mesh from becoming clogged by sticky or fine particles, ensuring a smooth flow of material through the screen.

3. Adjustable Parameters for Versatile Applications

The eccentric vibrator mechanism allows for easy adjustments to the screening process. By modifying the eccentricity and amplitude, operators can fine-tune the performance of the screen to match specific material types and screening requirements.

- Customizable Motion: Different materials, whether fine powders or coarse aggregates, can be effectively screened by adjusting the eccentricity to achieve the desired material flow and separation efficiency.

4. High Screening Efficiency

The swing screen offers high efficiency in terms of throughput, with the ability to handle larger quantities of material without compromising the quality of separation. This is achieved through its multi-dimensional movement and optimal material dispersion.

- Increased Throughput: With its efficient design, the swing screen can handle high-volume operations while maintaining excellent separation accuracy.

5. Gentle Handling for Fragile Materials

The swing screen’s motion is particularly advantageous for fragile materials that might break or crush under the harsh conditions of traditional high-frequency vibrating screens. The screen provides gentle, controlled movement to maintain the integrity of the material.

- Minimized Damage: Whether it's fragile food products or delicate chemicals, the swing screen ensures that the materials are handled with care, preventing breakage and preserving product quality.