In the world of industrial processing, from food production to mining operations, efficient material separation is critical to the success of any production line. One key component that plays a significant role in this process is the screen mesh. Designed to separate, filter, and sort materials based on their size, vibrating screens are a staple in industries that deal with large volumes of granular or powdery substances.

The vibrating screen mesh is a highly effective solution that not only improves screening efficiency but also guarantees satisfactory results in terms of product quality and operational productivity. The durability, precision, and versatility of the mesh contribute to its ability to meet the diverse needs of industries. This article will explore the key benefits of vibrating screen mesh and how it delivers optimal performance in various applications.

High Durability for Consistent Results

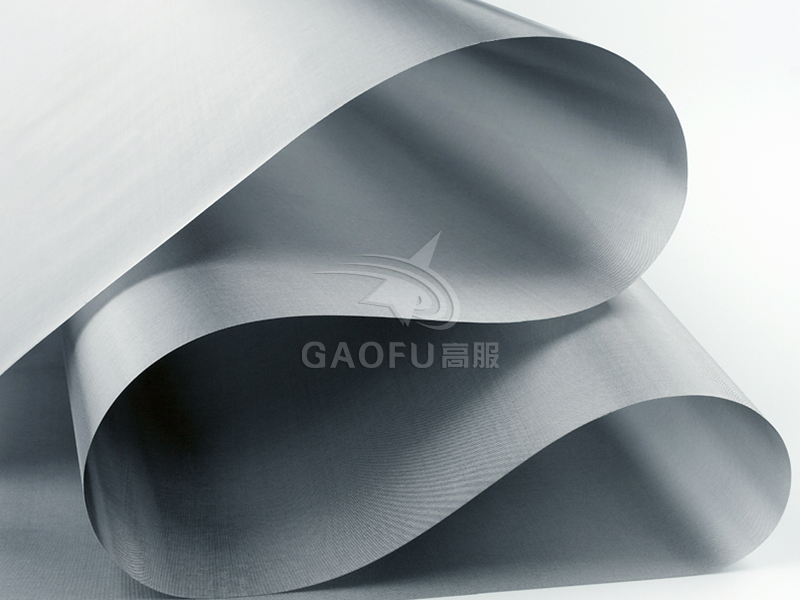

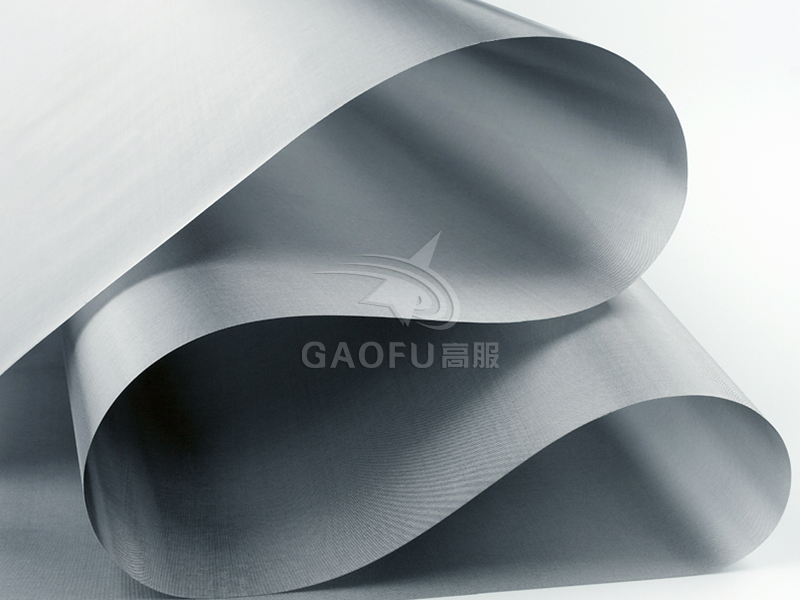

One of the standout features of vibrating screen mesh is its durability. In industries where continuous processing of abrasive materials such as minerals, chemicals, or granules is required, the mesh must withstand extreme conditions. The vibrating screen mesh is made from materials like stainless steel, polyurethane, or high-carbon steel, which are known for their resistance to wear and abrasion.

This high durability ensures that the mesh maintains its structural integrity even after prolonged use, resulting in consistent and reliable performance. With a longer lifespan and fewer replacements needed, businesses can enjoy significant cost savings while achieving continuous, high-quality output.

Moreover, the strong construction of the mesh minimizes the risk of breakage or failure during operation, thus preventing costly downtime and ensuring that production schedules remain on track.

Precision Screening for Optimal Material Separation

Another important aspect of the vibrating screen mesh is its ability to offer precision screening. With its carefully designed mesh sizes, it ensures that materials are accurately separated based on their size, eliminating the possibility of waste or contamination in the final product. Whether the task is separating fine powders or coarse granules, vibrating screens can be tailored to suit the specific needs of each application, providing consistent results each time.

In industries like pharmaceuticals, food processing, and mining, where particle size is crucial to the quality of the product, precise separation is essential. The mesh ensures that only the correctly sized materials pass through, improving yield and product quality. This precision not only enhances the final product but also reduces the need for reprocessing or waste disposal, contributing to cost efficiency.

Increased Efficiency for Higher Productivity

Vibrating screen mesh is not just about separating materials; it’s about doing so in the most efficient manner possible. The vibration mechanism that powers the screen mesh accelerates the separation process, ensuring that materials are sifted through quickly and efficiently.

The increased screening capacity that comes with vibrating screen mesh enables businesses to handle larger volumes of material with ease, ultimately boosting productivity. For industries that rely on high throughput, such as mining or aggregate processing, this enhanced efficiency translates into faster production rates and a reduction in operational costs.

By optimizing the flow of materials through the screen mesh, companies can ensure that their production lines run smoothly and continuously, without unnecessary interruptions. The increased throughput means that more material is processed in less time, leading to higher overall output and greater profitability.

Customizable for Diverse Applications

One of the unique features of the vibrating screen mesh is its customizability. Depending on the type of material being processed, the mesh size, shape, and material composition can be tailored to meet the specific requirements of the application.

For instance, in food processing, where hygiene is paramount, the vibrating screen mesh can be designed with easy-to-clean surfaces and corrosion-resistant materials to maintain product purity. In mining, where the mesh may need to handle large volumes of heavy materials, stronger and more robust mesh types are used to ensure long-term performance.

This flexibility makes the vibrating screen mesh an invaluable asset across a wide range of industries. By choosing the appropriate mesh configuration for the application, businesses can achieve the optimal performance and satisfactory results they need to stay competitive in their respective markets.

Cost-Effective and Energy Efficient

When it comes to long-term savings, vibrating screen mesh stands out as an energy-efficient solution. The mesh works in conjunction with vibrating motors, which use minimal energy while still delivering powerful results. This low energy consumption means that companies can maintain high output with relatively low operational costs.

Moreover, the reduced maintenance associated with durable vibrating screen mesh further contributes to cost savings. Fewer breakdowns and less frequent replacements mean that businesses can allocate their resources to other critical areas, such as expanding production capabilities or improving product quality.

Satisfactory Results Across Various Industries

The vibrating screen mesh is a crucial tool for industries that require effective material separation. Its ability to deliver satisfactory results in terms of product quality, efficiency, and cost savings makes it indispensable in industries like:

- Mining: For separating ores, sand, and gravel with high precision.

- Pharmaceuticals: For sifting powders and ensuring consistent product quality.

- Food Processing: For grading ingredients and ensuring that the final product meets strict quality standards.

- Chemical Industry: For separating fine powders and granules to ensure the purity of chemicals.

In each of these sectors, the vibrating screen mesh plays a pivotal role in ensuring high-quality production and increased operational efficiency, ultimately contributing to business growth and profitability.

The vibrating screen mesh is a highly effective solution that not only improves screening efficiency but also guarantees satisfactory results in terms of product quality and operational productivity. The durability, precision, and versatility of the mesh contribute to its ability to meet the diverse needs of industries. This article will explore the key benefits of vibrating screen mesh and how it delivers optimal performance in various applications.

High Durability for Consistent Results

One of the standout features of vibrating screen mesh is its durability. In industries where continuous processing of abrasive materials such as minerals, chemicals, or granules is required, the mesh must withstand extreme conditions. The vibrating screen mesh is made from materials like stainless steel, polyurethane, or high-carbon steel, which are known for their resistance to wear and abrasion.

This high durability ensures that the mesh maintains its structural integrity even after prolonged use, resulting in consistent and reliable performance. With a longer lifespan and fewer replacements needed, businesses can enjoy significant cost savings while achieving continuous, high-quality output.

Moreover, the strong construction of the mesh minimizes the risk of breakage or failure during operation, thus preventing costly downtime and ensuring that production schedules remain on track.

Precision Screening for Optimal Material Separation

Another important aspect of the vibrating screen mesh is its ability to offer precision screening. With its carefully designed mesh sizes, it ensures that materials are accurately separated based on their size, eliminating the possibility of waste or contamination in the final product. Whether the task is separating fine powders or coarse granules, vibrating screens can be tailored to suit the specific needs of each application, providing consistent results each time.

In industries like pharmaceuticals, food processing, and mining, where particle size is crucial to the quality of the product, precise separation is essential. The mesh ensures that only the correctly sized materials pass through, improving yield and product quality. This precision not only enhances the final product but also reduces the need for reprocessing or waste disposal, contributing to cost efficiency.

Increased Efficiency for Higher Productivity

Vibrating screen mesh is not just about separating materials; it’s about doing so in the most efficient manner possible. The vibration mechanism that powers the screen mesh accelerates the separation process, ensuring that materials are sifted through quickly and efficiently.

The increased screening capacity that comes with vibrating screen mesh enables businesses to handle larger volumes of material with ease, ultimately boosting productivity. For industries that rely on high throughput, such as mining or aggregate processing, this enhanced efficiency translates into faster production rates and a reduction in operational costs.

By optimizing the flow of materials through the screen mesh, companies can ensure that their production lines run smoothly and continuously, without unnecessary interruptions. The increased throughput means that more material is processed in less time, leading to higher overall output and greater profitability.

Customizable for Diverse Applications

One of the unique features of the vibrating screen mesh is its customizability. Depending on the type of material being processed, the mesh size, shape, and material composition can be tailored to meet the specific requirements of the application.

For instance, in food processing, where hygiene is paramount, the vibrating screen mesh can be designed with easy-to-clean surfaces and corrosion-resistant materials to maintain product purity. In mining, where the mesh may need to handle large volumes of heavy materials, stronger and more robust mesh types are used to ensure long-term performance.

This flexibility makes the vibrating screen mesh an invaluable asset across a wide range of industries. By choosing the appropriate mesh configuration for the application, businesses can achieve the optimal performance and satisfactory results they need to stay competitive in their respective markets.

Cost-Effective and Energy Efficient

When it comes to long-term savings, vibrating screen mesh stands out as an energy-efficient solution. The mesh works in conjunction with vibrating motors, which use minimal energy while still delivering powerful results. This low energy consumption means that companies can maintain high output with relatively low operational costs.

Moreover, the reduced maintenance associated with durable vibrating screen mesh further contributes to cost savings. Fewer breakdowns and less frequent replacements mean that businesses can allocate their resources to other critical areas, such as expanding production capabilities or improving product quality.

Satisfactory Results Across Various Industries

The vibrating screen mesh is a crucial tool for industries that require effective material separation. Its ability to deliver satisfactory results in terms of product quality, efficiency, and cost savings makes it indispensable in industries like:

- Mining: For separating ores, sand, and gravel with high precision.

- Pharmaceuticals: For sifting powders and ensuring consistent product quality.

- Food Processing: For grading ingredients and ensuring that the final product meets strict quality standards.

- Chemical Industry: For separating fine powders and granules to ensure the purity of chemicals.

In each of these sectors, the vibrating screen mesh plays a pivotal role in ensuring high-quality production and increased operational efficiency, ultimately contributing to business growth and profitability.