Tumbler Vibrating Screen: The Perfect Solution for Zirconia Screening at Just $3999

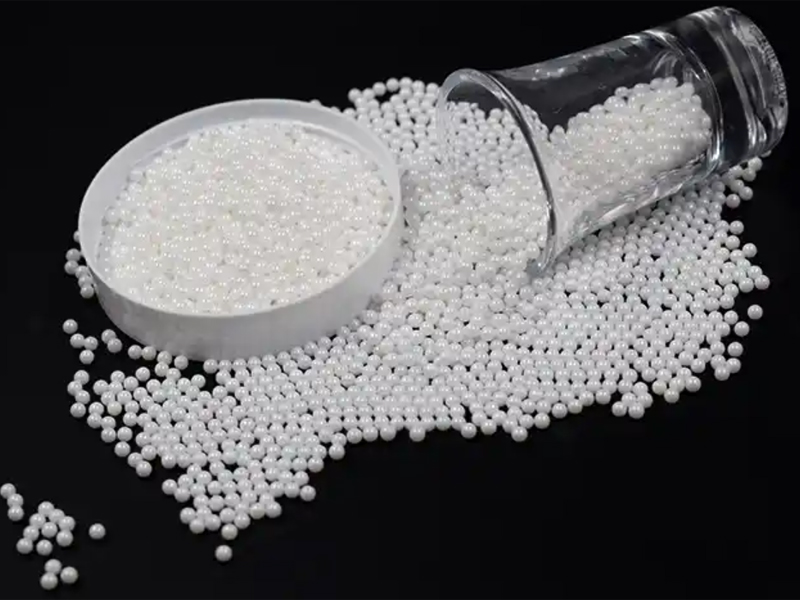

Zirconia, a high-performance material widely used in industries like ceramics, dental products, and advanced engineering, demands precise and efficient screening to ensure uniformity and quality. The tumbler vibrating screen has emerged as an ideal tool for zirconia screening, offering exceptional precision and performance at an incredible price of just $3999.

What is a Tumbler Vibrating Screen?

A tumbler vibrating screen mimics the motion of manual sieving, creating a gentle and efficient tumbling motion that separates particles by size. This advanced screening machine is designed for applications requiring high precision, such as zirconia powder, where uniform particle size is crucial for downstream applications.

Key Features of the Tumbler Vibrating Screen

1、High-Precision Screening

The tumbler screen achieves up to 99% screening efficiency, ensuring the zirconia powder is evenly classified and free of oversized particles or contaminants.

2、Gentle Sieving Motion

The circular tumbling motion minimizes particle breakage, preserving the integrity of zirconia powder while delivering accurate results.

3、Multi-Layer Design

The screen supports multiple layers, allowing simultaneous classification of zirconia into different size fractions, which improves process efficiency.

4、Low Operating Cost

At just $3999, the tumbler vibrating screen provides premium functionality at an affordable price, making it accessible for businesses of all sizes.

5、Durable and Reliable

Built with high-quality materials, the tumbler screen ensures long-term performance even in demanding industrial environments.

6、Customizable Options

With customizable mesh sizes and screen configurations, the machine adapts to meet specific zirconia screening requirements.

Advantages of Using a Tumbler Vibrating Screen for Zirconia

1、Enhanced Product Quality

The precise sieving process eliminates impurities and oversized particles, ensuring uniformity in zirconia powder, which is essential for applications like dental ceramics and technical ceramics.

2、Improved Efficiency

The high screening capacity of the tumbler screen allows for faster processing of zirconia powder, increasing production rates without compromising accuracy.

3、Reduced Material Waste

By effectively separating usable zirconia from contaminants or oversized particles, the tumbler screen minimizes material wastage, contributing to cost savings.

4、Low Maintenance Requirements

The robust design and user-friendly operation of the tumbler screen reduce maintenance needs, ensuring uninterrupted production and lower operational costs.

Applications of the Tumbler Vibrating Screen

The tumbler vibrating screen is tailored for industries requiring high-precision screening. Specific applications for zirconia include:

- Ceramics Industry: Grading zirconia powder for advanced ceramics used in industrial and decorative applications.

- Dental Products: Screening zirconia for dental crowns, bridges, and implants to ensure consistency in particle size.

- Industrial Applications: Classifying zirconia for use in abrasives, refractories, and electronic components.

Why Choose the Tumbler Vibrating Screen?

For manufacturers handling zirconia powder, the tumbler vibrating screen offers a cost-effective and high-performance solution. Its gentle motion, precision, and durability ensure optimal results, making it a valuable addition to any production line.

Priced at just $3999, this screening machine delivers premium functionality at an affordable cost, making it an excellent choice for small and medium-sized businesses looking to enhance their screening processes without stretching their budgets.