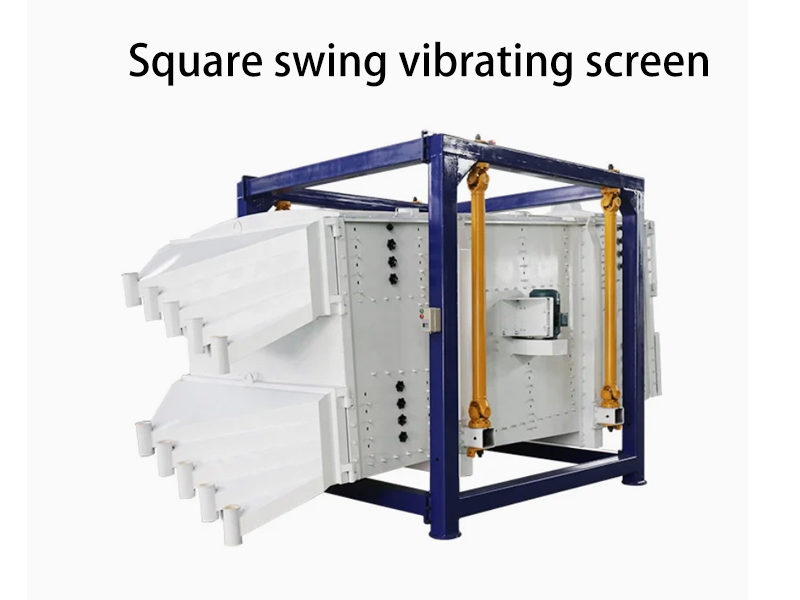

In the field of industrial screening, efficiency, durability, and cost-effectiveness are key factors in determining the best equipment for large-scale material processing. The square swing vibrating screen stands out as a superior solution, offering exceptional performance in high-capacity screening operations.

Superior Advantages of the Square Swing Vibrating Screen

1. Extended Service Life of the Screen Mesh

One of the most significant advantages of this equipment is its long-lasting screen mesh. Traditional screening machines often suffer from frequent wear and tear due to high-frequency vibrations and continuous material flow. However, the square swing vibrating screen is designed to minimize stress on the mesh, reducing the chances of premature damage. This results in longer operational life, fewer replacements, and increased cost savings for businesses.

2. Low Maintenance Costs

Maintenance is a crucial factor when choosing screening equipment. High maintenance costs can significantly impact production efficiency and profitability. The square swing vibrating screen features a robust and stable design that requires minimal maintenance. Its gentle screening motion reduces wear on components, ensuring low operational costs and higher return on investment over time.

3. Multi-Layer Stacking for Precise Output

Unlike conventional screening machines, the square swing vibrating screen allows for multi-layer stacking, enabling simultaneous classification of different particle sizes. This feature enhances screening efficiency by separating materials more precisely, reducing processing time, and improving product quality. Whether used in mining, chemical, or food industries, this multi-layer capability ensures optimal performance for various screening applications.

4. High Output for Large-Scale Production

For industries that require large-scale material screening, high output capacity is a crucial consideration. The square swing vibrating screen is specifically designed to handle large quantities of material with maximum efficiency. Its unique swinging motion ensures thorough material distribution, leading to higher screening accuracy and increased productivity. With this equipment, businesses can achieve higher throughput without compromising on screening precision.

Why Choose the Square Swing Vibrating Screen?

The square swing vibrating screen is not just another piece of screening equipment—it is a high-performance screening expert that offers:

- Extended mesh lifespan, reducing replacement costs

- Lower maintenance requirements, leading to cost savings

- Multi-layer screening capabilities, improving efficiency

- High-capacity output, meeting large-scale production demands

With its innovative design and superior performance, the square swing vibrating screen is the ideal choice for industries looking to enhance their screening processes. Its ability to handle large volumes efficiently while minimizing maintenance costs makes it a valuable asset for businesses aiming for increased productivity and profitability.

Investing in the right screening equipment is essential for optimizing operations. With the square swing vibrating screen, companies can maximize output, reduce operational expenses, and achieve superior screening results—making it the true expert in high-capacity screening.