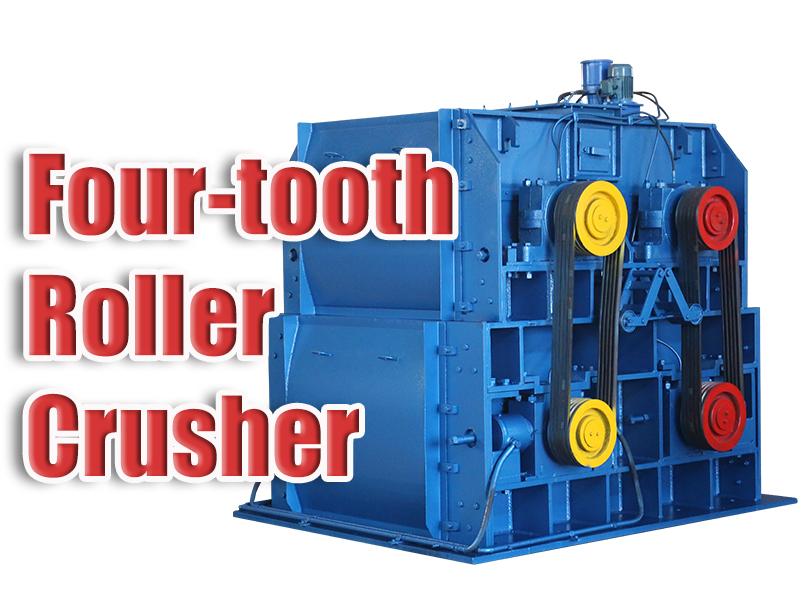

The four-tooth roller crusher is an essential piece of equipment in industries that require high efficiency, low maintenance, and precise particle size reduction. Known for its robust design and advanced features, the four-tooth roller crusher stands out in various applications such as coal, mining, and chemical industries. This article highlights the key advantages of the four-tooth roller crusher, focusing on its high stability, low over-crushing rate, ease of maintenance, and cost-effectiveness.

1. High Stability and Consistent Output

One of the most notable advantages of the four-tooth roller crusher is its high stability and consistent output. The crusher operates smoothly and efficiently, ensuring that it can handle large volumes of materials without interruptions. Its non-blocking design ensures that even when processing materials with varying hardness levels, the machine remains operational without the risk of clogs or jams.

The uniform feeding system ensures that material is fed consistently into the crushing chamber, preventing uneven wear on the machine and improving its overall performance. This feature ensures the production of consistent-sized particles, making the machine ideal for operations that require a steady and high-quality output.

2. Simple Structure and Low Maintenance

The four-tooth roller crusher is designed with simplicity in mind. Its straightforward structure allows for easy operation and minimal maintenance requirements. This low maintenance design makes it an attractive option for industries seeking a reliable and hassle-free solution for crushing. The machine requires less frequent repairs compared to other types of crushers, thus reducing operational downtime and maintenance costs.

The ease of maintenance not only saves time and labor costs but also contributes to the long-term reliability of the machine. This advantage ensures that the crusher can operate continuously with minimal interruptions, enhancing productivity and efficiency.

3. Low Over-Crushing Rate and Excellent Particle Size

Another key feature of the four-tooth roller crusher is its low over-crushing rate. Unlike traditional crushers that tend to produce excess fines, the four-tooth roller crusher delivers a highly consistent particle size with minimal fine particles. This feature is particularly beneficial in industries that require a specific range of particle sizes for further processing.

The low over-crushing rate ensures that the material is broken down to the desired size without excessive grinding, which helps in preserving the quality of the final product. The resulting product is uniform, making it suitable for applications where the final particle size is critical.

4. Smooth, Intelligent, and Reliable Operation

The four-tooth roller crusher is engineered for smooth and intelligent operation. The machine is equipped with advanced technology that allows for intelligent operation control, ensuring that the crusher operates at optimal performance levels. This intelligent design helps in achieving higher crushing efficiency while reducing energy consumption.

In addition to its smooth operation, the machine is also equipped with advanced balancing technology, ensuring that it can adapt to varying material hardness and prevent damage to its internal components. This makes the crusher reliable and capable of withstanding harsh working conditions, making it an ideal solution for heavy-duty industrial applications.

5. Cost-Effective Investment

The four-tooth roller crusher offers a low initial investment cost compared to other crushers, making it an affordable choice for companies looking to upgrade their equipment. Despite its lower upfront cost, the machine provides high efficiency and reliable performance, offering significant returns on investment over time.

Its low operating costs and minimal maintenance requirements further contribute to its cost-effectiveness. Companies can save money on repairs, maintenance, and energy consumption, making the four-tooth roller crusher a financially viable option for industries aiming to boost their productivity without breaking the bank.

6. Long Service Life and Durable Performance

With its robust construction and high-quality materials, the four-tooth roller crusher is designed to deliver a long service life. The durable design ensures that the crusher can handle heavy-duty operations without experiencing wear and tear quickly. Additionally, the machine is equipped with advanced components that contribute to its extended operational lifespan.

The uniform feeding system and anti-wear materials used in the construction of the four-tooth roller crusher help minimize wear on critical parts, such as the rollers and tooth plates. As a result, the machine can continue to operate efficiently for a long period, providing companies with long-term reliability and reduced downtime.

7. High Energy Efficiency and Environmentally Friendly

In addition to its durability and low maintenance, the four-tooth roller crusher is highly energy-efficient. The machine's design minimizes power consumption while maximizing output, making it an environmentally friendly option for companies looking to reduce their carbon footprint.

The energy-efficient operation not only lowers electricity costs but also supports sustainable production practices. By reducing energy consumption and minimizing waste, the four-tooth roller crusher contributes to a cleaner and more eco-friendly industrial process.

8. Liquid Spring Balance and Protection System

The four-tooth roller crusher features a liquid spring balance system, which helps maintain the crusher's stability during operation. This system ensures that the crusher operates at optimal pressure and speed, preventing mechanical overload or damage.

In addition, the anti-failure protection system allows the crusher to self-adjust when encountering materials that cannot be processed, such as large lumps or foreign objects. The machine’s ability to automatically retract and release non-crushable materials ensures continuous operation without causing damage to the machine, further enhancing its reliability and lifespan.