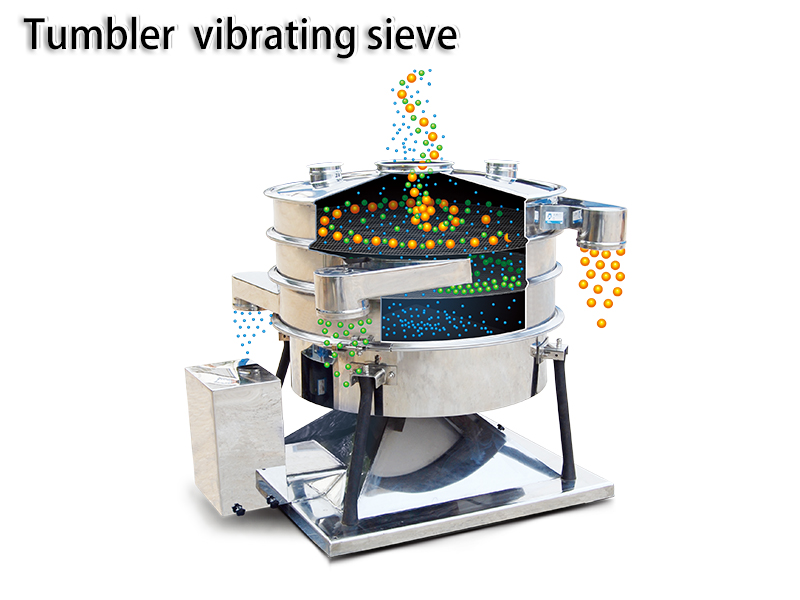

In precision screening applications, one of the most challenging issues arises when particle sizes approach 30 microns. At this fine level, mesh clogging becomes a critical problem, leading to decreased efficiency and potential disruptions in production. The Tumbler Vibrating Sieve is designed to tackle this issue with its comprehensive and highly effective cleaning systems, ensuring smooth, uninterrupted operation and maintaining optimal screening performance.

Innovative Cleaning Systems for Maximum Efficiency

To combat mesh clogging, the Tumbler Vibrating Sieve incorporates multiple advanced self-cleaning mechanisms, allowing for efficient processing of sticky, electrostatically charged, and ultra-fine materials. These cleaning systems include:

✔ Rubber Ball Cleaning System – Uses bouncing rubber balls beneath the screen to dislodge trapped particles.

✔ Brush Cleaning System (Independent Gear-Driven) – A slow-moving brush system gently sweeps the screen surface, preventing clogging.

✔ Air Jet Cleaning System – Uses high-speed air streams to blow away fine particles and maintain open mesh holes.

✔ Ultrasonic Cleaning System – High-frequency ultrasonic waves break up adhered particles for enhanced separation.

✔ Combined Air Jet & Brush Cleaning System – A hybrid approach that combines air jets with mechanical brushing for maximum efficiency.

For highly sticky or electrostatically charged materials, partial or full air-jet cleaning is often recommended to ensure continuous and effective operation.

Low-Noise, Smooth, and Energy-Efficient Performance

The Tumbler Vibrating Sieve is designed with a modular structure and operates at low speeds, ensuring quiet and smooth performance.

✔ Noise levels remain between 60~70 dB, making it one of the quietest sieving solutions available.

✔ TEFC (Totally Enclosed Fan-Cooled) motors ensure reliability and efficiency, even in demanding environments.

✔ Energy-efficient design –

- Smaller models operate with just 0.25 kW of power.

- Larger models, which can weigh up to 2 tons, require only 5.5 kW of power, optimizing energy consumption.

Why Choose the Tumbler Vibrating Sieve?

- Superior Anti-Clogging Technology – Multiple cleaning systems ensure uninterrupted screening, even for fine and sticky materials.

- Ultra-Quiet Operation – Noise levels between 60~70 dB provide a comfortable and non-disruptive working environment.

- Energy-Efficient Motor – Low power consumption, even in large-scale operations.

- Reliable & Durable Design – The low-speed modular structure ensures long-lasting performance with minimal maintenance.