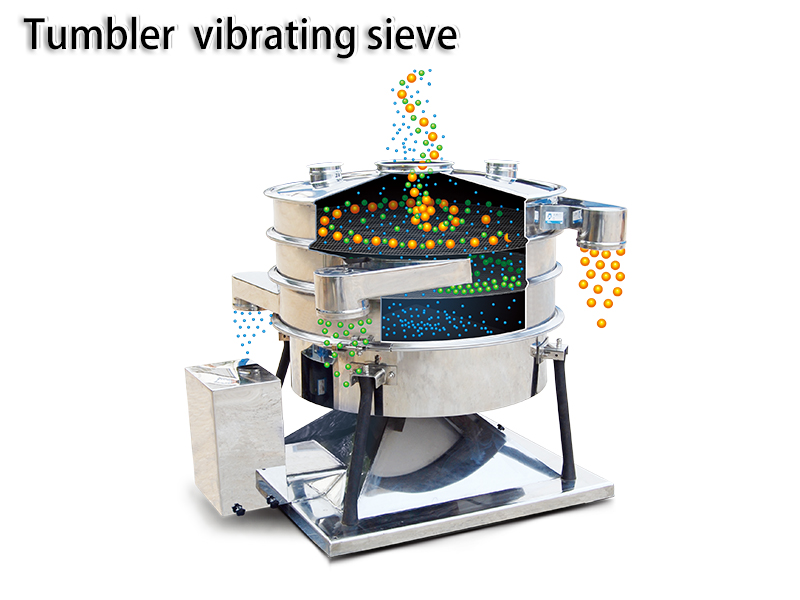

Stainless Steel Tumbler Vibrating Screen, a reliable and efficient screening solution designed to meet the high demands of various industries. This advanced screening equipment combines robust performance with delicate handling, ensuring that material damage is minimized while achieving high throughput and precision. Whether you are involved in powder processing, food manufacturing, chemicals, or any industry that requires accurate particle classification, the Stainless Steel Tumbler Vibrating Screen is an excellent choice for achieving superior separation with minimal product degradation.

High Throughput with Single and Multi-Layer Screening

One of the standout features of the Stainless Steel Tumbler Vibrating Screen is its ability to perform both single-layer and multi-layer high-yield screening. Whether you need to process a small batch of fine particles or a large volume of bulk materials, this screen offers flexibility to handle various capacities and material types. The multi-layer configuration allows you to separate different sizes of particles simultaneously, improving efficiency and reducing the need for additional processing steps. This makes it an ideal solution for industries that require precise and continuous separation across a wide range of materials.

The Stainless Steel Tumbler Vibrating Screen’s high production capacity ensures that large volumes of materials can be processed in a relatively short period, reducing downtime and increasing productivity. At the same time, its precision ensures that each layer of the screen accurately separates coarse and fine particles, providing consistent results throughout the entire production process.

Accurate Particle Classification for Precision Sorting

With the Stainless Steel Tumbler Vibrating Screen, you can achieve accurate classification of particles based on size, ensuring that both coarse and fine particles are sorted with precision. The equipment features a unique tumbling motion that mimics manual sieving but with much higher efficiency and consistency. This motion allows the materials to move across the screen in a gentle and even manner, preventing material breakage and ensuring that delicate particles remain intact.

The tumbler screen is particularly effective when dealing with fragile or easily damaged materials, such as pharmaceutical powders, food products, or fine chemicals. The low-impact screening process ensures that even the most delicate particles are separated without being crushed or distorted, which is critical for industries that require high product integrity and quality.

By accurately classifying particles into distinct size groups, businesses can ensure that each material is processed to meet the required specifications, minimizing waste and enhancing the final product quality. Whether you are sorting granular, powdery, or delicate materials, the Stainless Steel Tumbler Vibrating Screen offers the precision you need to achieve optimal results.

Low Noise and Low Energy Consumption

Another key advantage of the Stainless Steel Tumbler Vibrating Screen is its low noise and low energy consumption. Traditional vibrating screens can often be noisy and consume large amounts of energy, but the tumbler screen operates with minimal noise and reduced power requirements. This makes it ideal for industries that require a quieter working environment and seek to lower their overall energy costs.

The reduced noise levels contribute to a more comfortable and safer workplace, allowing operators to focus on their tasks without excessive noise interference. Furthermore, the energy-efficient design of the Stainless Steel Tumbler Vibrating Screen helps businesses reduce their operating costs while maintaining high throughput and efficient material separation.

Durable Stainless Steel Construction

As the name suggests, the Stainless Steel Tumbler Vibrating Screen is built with high-quality stainless steel, which ensures durability and corrosion resistance, even in challenging environments. Stainless steel is known for its strength and long service life, which makes this screen ideal for applications where high durability is required. The robust construction allows the equipment to withstand the rigors of continuous operation, providing long-term reliability and minimizing the need for frequent repairs or replacements.

Additionally, stainless steel is easy to clean and maintain, ensuring that the Tumbler Vibrating Screen remains in top condition throughout its operational life. This makes it a cost-effective solution for businesses that require both performance and longevity from their screening equipment.

Gentle Handling of Materials

One of the key selling points of the Stainless Steel Tumbler Vibrating Screen is its ability to handle materials gently. The tumbling action, combined with its low impact design, ensures that materials are processed without causing any damage. This is especially important when handling delicate or fragile materials, such as food products or fine powders, which could be crushed or degraded by more aggressive screening methods.

By minimizing material damage, businesses can maintain the integrity of their products, ensuring that the final output meets quality standards and customer expectations. The Tumbler Vibrating Screen offers a reliable solution for applications where delicate materials need to be handled with care.