Copper chrome black pigment powder is widely used in coatings, ceramics, plastics, and other industrial applications where color consistency and particle uniformity are critical. However, due to its fine particle size and tendency to clump, traditional screening methods often struggle with mesh clogging, inconsistent separation, and material contamination when switching between different pigments.

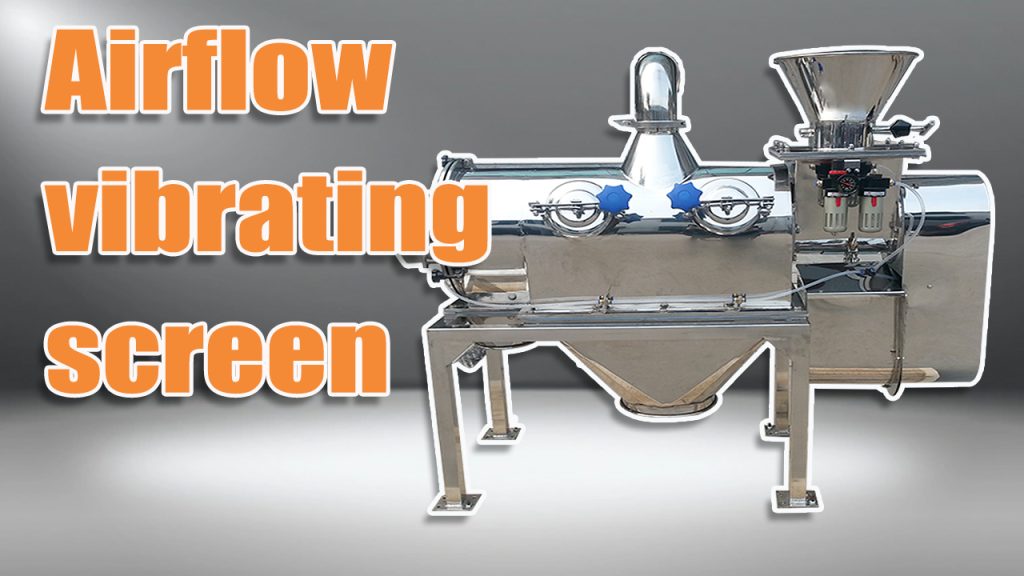

To address these challenges, our Airflow Vibrating Sieve provides an efficient, precise, and contamination-free screening solution for copper chrome black pigment powder. With its easy-to-clean design, it is particularly well-suited for multi-variety, small-batch production, ensuring that each pigment maintains its purity, consistency, and quality.

Why Our Airflow Vibrating Sieve is Ideal for Copper Chrome Black Pigment Powder?

1. Superior Screening for Fine Pigment Powders

- Traditional sieving methods often struggle with fine and dense pigment powders, leading to mesh clogging and inefficient screening.

- Our airflow vibrating sieve uses a combination of airflow and vibration technology to ensure that copper chrome black pigment powder is efficiently separated, achieving high-precision classification.

2. Easy to Clean & Ideal for Multi-Variety, Small-Batch Production

- In industries that handle multiple pigment types, cross-contamination between different batches can be a major concern.

- Our airflow vibrating sieve features a quick and easy cleaning system, allowing for fast material changeovers and ensuring that each batch remains uncontaminated.

- This makes it perfect for small-batch production, where frequent switching between different pigment types is required.

3. Prevents Material Cross-Contamination

- Unlike traditional screening machines that may retain material residues, our airflow sieve is designed to minimize material buildup inside the machine.

- With its smooth internal surfaces and efficient airflow design, it effectively reduces the risk of cross-contamination between different pigment powders.

4. Maintains Pigment Purity & Consistency

- Copper chrome black pigment is often used in applications where color uniformity and fine particle distribution are critical.

- Our airflow vibrating sieve ensures precise particle classification, leading to consistent color quality and improved product performance in coatings, plastics, ceramics, and more.

5. Reduces Maintenance & Downtime

- The self-cleaning cyclone airflow system helps to prevent mesh clogging, reducing the need for frequent maintenance.

- With its efficient design, easy access for cleaning, and durable construction, our sieve is built for long-term, hassle-free operation.

Industries That Benefit from Our Airflow Vibrating Sieve

Our Airflow Vibrating Sieve is widely used in industries that require precise screening of fine pigment powders, including:

✔ Coatings & Paints – Ensuring fine, uniform pigment particles for consistent color application.

✔ Ceramics & Glass – Maintaining color consistency and particle uniformity in ceramic production.

✔ Plastics & Polymers – Enhancing color dispersion and quality in plastic formulations.

✔ Chemicals & Specialty Pigments – Providing high-precision classification for industrial pigment applications.

Why Choose Our Airflow Vibrating Sieve for Pigment Powder?

🔹 Optimized for Fine Pigment Screening – Ensures high-precision separation of ultra-fine pigment particles.

🔹 Easy to Clean Design – Perfect for multi-variety, small-batch production, allowing quick material changeovers.

🔹 Prevents Cross-Contamination – Reduces the risk of pigment mixing and color inconsistencies.

🔹 Self-Cleaning System – Prevents mesh clogging, reducing maintenance and downtime.

🔹 Ensures Color & Particle Consistency – Helps maintain high-quality pigment distribution.

Upgrade Your Pigment Powder Screening Process Today!

If you are looking for a high-efficiency, easy-to-clean, and contamination-free screening solution for copper chrome black pigment powder, our Airflow Vibrating Sieve is the perfect choice. With its advanced airflow technology, fast cleaning system, and precise separation capabilities, it ensures higher productivity, improved pigment purity, and long-term reliability.