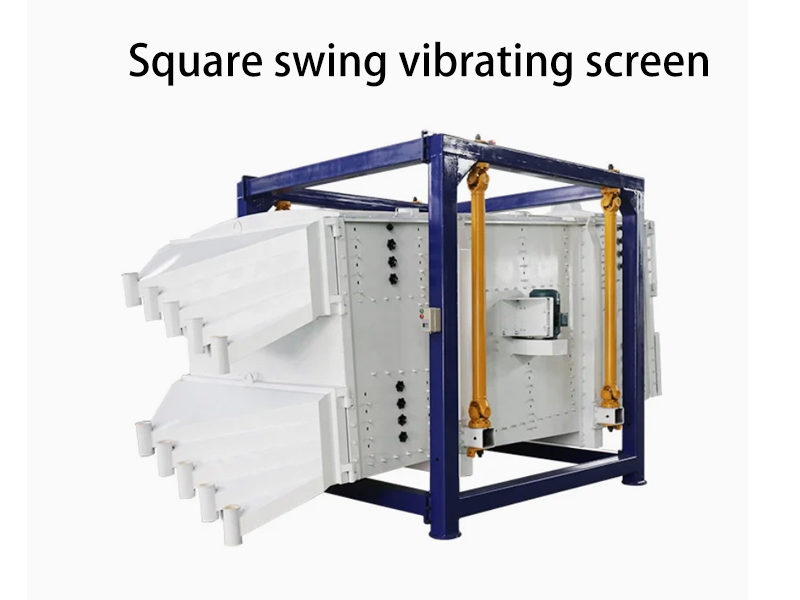

The square swing vibrating screen is a highly versatile and efficient screening machine widely used in various industries, including chemical processing, new materials, metallurgy, metal powder, and mineral powder. Due to its advanced design and innovative screening technology, it has become a crucial tool for industries requiring precise and efficient material separation. One of the key advantages of this equipment is its ability to replace multiple traditional screening machines, effectively doubling production capacity while maintaining high screening accuracy.

Key Features and Advantages

1. High Efficiency and Large Output

Unlike conventional vibrating screens, the square swing vibrating screen is designed to handle larger volumes of material with greater efficiency. By simulating the natural hand-sieving motion, the machine ensures thorough material separation while reducing screen blockage and material loss.

One of the most significant benefits of this screening machine is its ability to replace multiple smaller screens, allowing a single unit to achieve double the production output. This not only enhances operational efficiency but also reduces energy consumption and maintenance costs.

2. Versatile Applications Across Multiple Industries

The square swing vibrating screen is widely used in industries that require high-precision screening of fine and ultra-fine materials. Some of its most common applications include:

- Chemical and New Materials Industry: Used for screening fine powders and ensuring material purity in chemical processing.

- Metallurgy and Metal Powder Processing: Ideal for separating metal powders, ensuring uniformity in particle size distribution.

- Mineral Powder Industry: Efficiently classifies and dehydrates mineral powders, improving processing efficiency.

3. Unique Swing Motion for Precise Screening

The machine operates using a unique swinging motion, which closely resembles the manual sieving process. This motion enables:

- Gentle handling of fragile or delicate materials, preventing breakage.

- Higher screening accuracy, ensuring only the correct particle sizes pass through.

- Reduced wear and tear, extending the lifespan of the screen and reducing maintenance costs.

4. Cost-Effective and Space-Saving Design

By replacing multiple traditional vibrating screens with a single square swing screen, industries can:

- Save space in production facilities, optimizing factory layouts.

- Reduce maintenance efforts and operational costs, as fewer machines mean less downtime and lower energy consumption.

- Increase overall productivity, achieving higher throughput with a single piece of equipment.