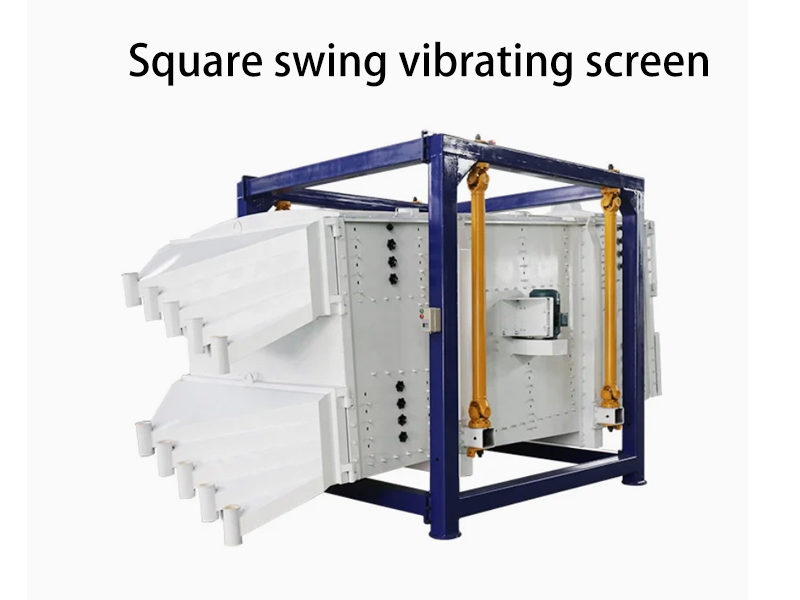

In industries where material separation and grading are essential, having the right screening equipment can make all the difference in achieving high-precision results. The Square Swinging Screen has become the go-to solution for businesses that require accurate material classification and superior screening performance. This advanced equipment is designed to meet the most stringent screening demands, offering a unique combination of precision, efficiency, and reliability.

Meeting High-Precision Screening Demands

The Square Swinging Screen is specifically engineered to handle applications where accurate separation of materials by size is critical. In industries such as pharmaceuticals, chemicals, food processing, and mining, precise grading is not only important for meeting production goals but also for ensuring product quality and consistency. For these sectors, a slight variation in material grading could result in significant operational issues or compromised product quality.

Unlike traditional screening methods, the Square Swinging Screen delivers exceptional screening accuracy. Its swinging motion, which mimics the natural action of hand sieving, ensures that materials are uniformly distributed across the screen surface, preventing clogging or inefficient separation. This precise distribution leads to accurate sizing and efficient sorting of particles, meeting even the most demanding grading specifications.

Key Features of the Square Swinging Screen

1. Unmatched Screening Precision

The most important feature of the Square Swinging Screen is its ability to provide high-precision screening. The screen's unique swing motion ensures that particles are carefully sifted through the mesh without the risk of material buildup or blockages. This precise motion guarantees that even the smallest and finest particles are effectively separated, providing consistent, reliable results every time.

This makes the Square Swinging Screen the perfect solution for high-precision applications where even the smallest deviation in material separation could affect the final product. Whether you are dealing with fine powders or coarse materials, the screen ensures that each particle is correctly classified to meet the required standards.

2. Increased Efficiency and Throughput

While precision is important, efficiency in material processing is equally essential. The Square Swinging Screen offers high throughput without sacrificing accuracy. Its larger screening surface and optimized design allow for the processing of greater volumes of material in a shorter amount of time, thus boosting overall productivity.

Thanks to its multi-layer design, the screen can handle different particle sizes in one operation, significantly reducing the need for additional equipment or multiple screening stages. This multi-layer screening capability not only increases the overall efficiency of the process but also reduces the time required to achieve the desired level of material separation.

3. Versatility Across Industries

The Square Swinging Screen is highly versatile and can be used across a range of industries that require high-precision material separation. Whether in the food industry for sorting grains and spices, in the chemical industry for separating powders, or in the mining sector for grading minerals, the Square Swinging Screen excels in a wide range of applications.

Its ability to handle both coarse and fine materials makes it an ideal choice for industries that require precise separation across varying particle sizes. This versatility allows businesses to use the same equipment for multiple screening tasks, simplifying operations and reducing the need for specialized machinery.

4. Reduced Maintenance and Longevity

A critical factor in maintaining high-precision screening is ensuring that the equipment operates continuously without frequent maintenance. The Square Swinging Screen is built with durable, high-quality materials designed to withstand wear and tear, even in the most demanding environments. The screen's efficient design ensures minimal material buildup, reducing the chances of clogging and enhancing its overall lifespan.

With low maintenance needs, the Square Swinging Screen allows businesses to focus on production rather than downtime or costly repairs. This reliability and extended service life ensure that businesses get the most out of their investment, maintaining consistent and efficient screening performance over time.

5. Cost-Effective Screening Solution

Achieving high precision in screening does not have to come at a high cost. The Square Swinging Screen provides a cost-effective solution by offering long-term reliability, efficiency, and versatility. Its ability to handle multiple screening tasks and process large volumes of materials in a short time means businesses can achieve high-quality results while keeping operating costs in check.

Additionally, the reduced need for frequent repairs and lower maintenance requirements make the Square Swinging Screen a budget-friendly choice for businesses that require precision without compromising on cost-efficiency.