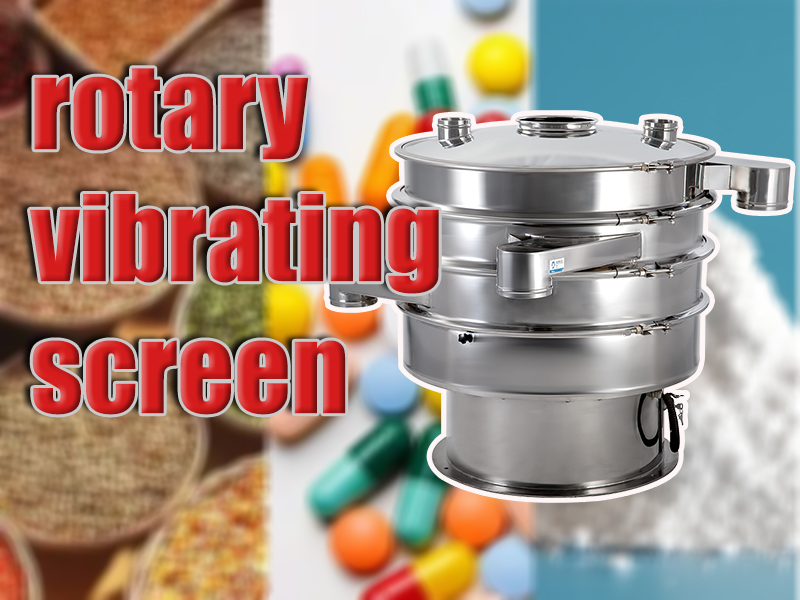

The rotary vibrating screen is a versatile and efficient screening machine designed for bulk material separation across multiple industries. This advanced equipment is widely used for screening, filtering, and grading various materials, making it an essential tool in industries such as food processing, pharmaceuticals, chemicals, metallurgy, and environmental protection.

One of the key advantages of the rotary vibrating screen is its ability to operate continuously, ensuring high efficiency and uninterrupted material processing. Whether used for dry or wet screening, this machine delivers consistent performance, improving overall production efficiency and product quality.

Key Features and Advantages

1. Continuous Operation for Maximum Productivity

Unlike some traditional screening equipment that requires frequent stops for adjustments or maintenance, the rotary vibrating screen is designed for continuous operation. This allows industries to increase processing capacity, minimize downtime, and maintain a steady production flow.

By enabling uninterrupted screening and filtration, this machine significantly enhances efficiency in large-scale material handling, making it a preferred choice for high-volume industries.

2. Dual Function: Screening and Filtration

The rotary vibrating screen is a multi-functional piece of equipment that can be used for both:

- Screening: Separates materials into different particle sizes, ensuring precise classification of bulk materials.

- Filtration: Efficiently removes impurities from liquids and semi-liquid substances, making it ideal for applications such as food and beverage processing, pharmaceuticals, and wastewater treatment.

This dual functionality makes the rotary vibrating screen an essential tool for industries requiring both solid-liquid separation and particle size classification.

3. Wide Range of Industrial Applications

Due to its high screening precision, adaptability, and efficiency, the rotary vibrating screen is extensively used in multiple industries, including:

- Food Processing: Screening and filtering of flour, sugar, spices, starch, coffee powder, and food additives.

- Pharmaceutical Industry: Ensuring uniform particle size and purity of medical powders, capsules, and herbal extracts.

- Chemical Industry: Classifying and filtering chemical powders, coatings, pigments, and resin materials.

- Metallurgy and Mining: Screening metal powders, minerals, and abrasives for industrial use.

- Wastewater Treatment: Filtering solid waste from liquids in environmental protection industries.

4. High Screening Efficiency and Precision

The rotary vibrating screen uses three-dimensional vibration technology, which ensures that materials move in circular, horizontal, and vertical motions. This enhances the screening efficiency and precision, allowing even the finest particles to be effectively separated.

By utilizing customizable mesh sizes and multi-layer screening, this machine enables industries to process materials with different particle sizes simultaneously, improving overall productivity and product quality.

5. Easy Maintenance and Long Service Life

- Durable Construction: Built with high-quality stainless steel or carbon steel for enhanced durability and resistance to wear and corrosion.

- Quick Screen Replacement: Designed for easy disassembly, allowing fast screen changes and reduced downtime.

- Low Energy Consumption: Operates efficiently with minimal power usage, making it a cost-effective solution for material processing.