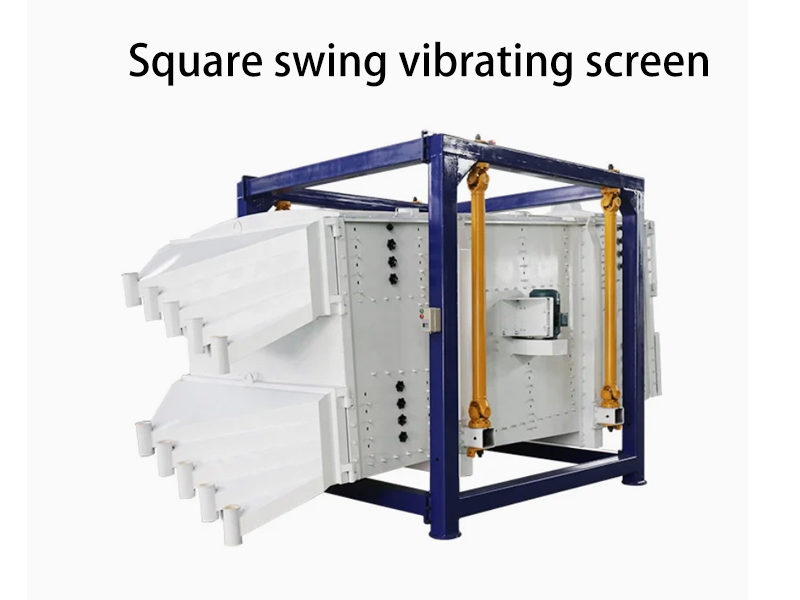

The square swing vibrating screen is a highly efficient screening solution widely used in industries such as mineral powder processing, salt and sugar refining, abrasives manufacturing, and animal feed production. Designed for precision and high-capacity screening, this machine ensures uniform particle separation, making it an essential tool for industries that demand accurate material classification.

Unlike conventional vibrating screens, the square swing vibrating screen utilizes a unique circular motion mechanism, where the exciter generates a reciprocating rotary movement that is transferred to the screen surface. This motion rapidly disperses materials at the front of the screen, improving screening efficiency and throughput. With its high reliability, long service life, and exceptional precision, this screening equipment is particularly suited for the mining and mineral processing industries.

Key Features and Advantages

1. Unique Swing Motion for High-Efficiency Screening

The defining feature of the square swing vibrating screen is its swinging motion, which simulates a manual sieving process. This movement provides:

- Gentle material handling, reducing damage to fragile or sensitive materials.

- Rapid dispersion of particles, ensuring materials are evenly distributed across the screen surface.

- Higher screening precision, effectively separating fine and coarse particles.

This motion makes it particularly effective for bulk materials, such as mineral powders, abrasives, and crystalline substances like salt and sugar.

2. Wide Range of Industrial Applications

The square swing vibrating screen is designed to meet the diverse needs of multiple industries:

- Mining & Mineral Processing: Efficiently classifies ore powders, silica sand, and other mineral-based materials.

- Salt & Sugar Industry: Ensures precise particle sizing for food-grade and industrial-grade salt and sugar production.

- Abrasive Manufacturing: Separates grit and fine abrasives, ensuring product consistency in industrial applications.

- Animal Feed Production: Helps classify different feed ingredients for uniform blending and quality assurance.

3. High Screening Efficiency and Capacity

Thanks to its reciprocating rotary motion, the square swing vibrating screen significantly improves screening efficiency:

- Even material distribution across the screen prevents clogging and ensures a continuous flow of materials.

- High throughput capacity, making it ideal for large-scale industrial operations.

- Precise separation of fine and coarse materials, ensuring consistent product quality.

Compared to traditional linear and circular vibrating screens, the square swing vibrating screen offers superior efficiency in handling fine and lightweight materials.

4. Durable Construction and Low Maintenance

- Heavy-duty frame and components: Built to withstand demanding industrial conditions.

- Low vibration impact: Reduces stress on the machine, extending its service life.

- Easy screen replacement: Modular design allows for quick mesh changes, minimizing downtime.

- Energy-efficient operation, reducing power consumption while maintaining high productivity.