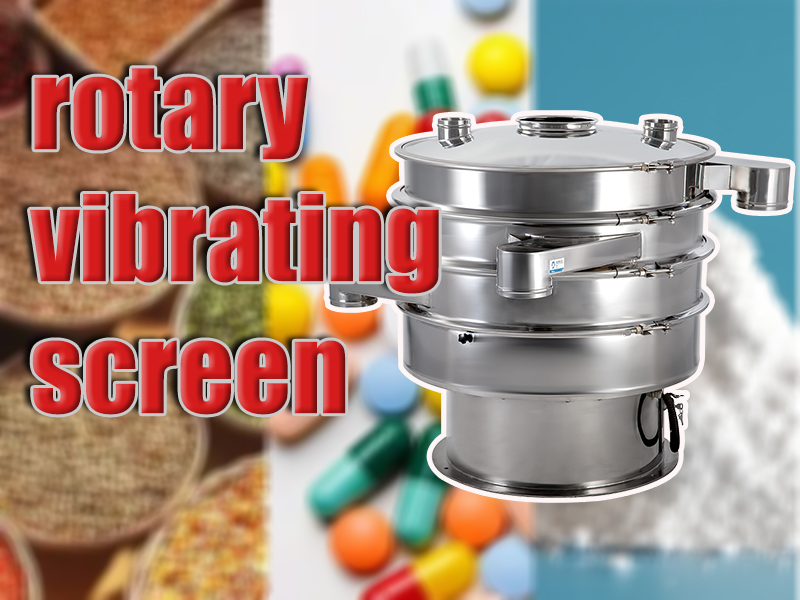

The rotary vibrating screen is a highly efficient and versatile equipment used in various industries for screening and filtering materials. Its ability to handle a wide range of materials— from granular powders to sticky substances— makes it indispensable for many production processes. This machine can sieve materials as fine as 600 mesh or 0.02mm and filter down to 5 microns, making it suitable for a variety of applications that require precise particle separation and size classification.

In this article, we will explore the working principles, applications, and benefits of the rotary vibrating screen in screening and filtering processes across different industries.

Wide Range of Applications

The rotary vibrating screen is designed to efficiently screen and filter a broad spectrum of materials. Its versatility allows it to be used for both dry and wet materials, including powders, granules, and pastes, within certain range specifications.

1. Screening of Granular Materials and Powders

The rotary vibrating screen is highly effective at separating and classifying granular materials and powders. It can screen materials as fine as 600 mesh (0.02mm) for applications that require high precision, such as in the pharmaceutical, chemical, and food industries.

- Fine Powder Screening: The ability to filter down to very fine sizes ensures that even micron-level particles can be screened with ease.

- High Throughput: Despite handling fine materials, the screen can process large volumes, allowing for continuous operations.

2. Filtering Liquids and Slurries

Rotary vibrating screens are also capable of filtering liquids and slurries with a high degree of efficiency. The ability to filter particles down to 5 microns makes this machine perfect for industries such as wastewater treatment, chemical filtration, and food processing.

- Liquid and Paste Filtration: The rotary vibrating screen separates solid contaminants from liquids or pastes, ensuring clean, filtered outputs for further use.

- Precision Filtration: It can filter materials to very fine levels, such as separating small particles in paint or pharmaceutical suspensions.

3. Grading and Sorting by Size

The rotary vibrating screen’s ability to be equipped with multiple layers of mesh makes it a powerful tool for grading and sorting materials into different size categories. This multi-layer design allows for simultaneous sorting of up to six different particle sizes.

- Multi-Grade Screening: The screen can be configured with one to five layers, making it ideal for multi-grade classification of materials, from coarse to fine.

- Efficient Sorting: It can separate materials in a single operation, increasing productivity and reducing processing time.

Key Features and Advantages

1. High Screening Efficiency

Rotary vibrating screens offer high screening efficiency due to their advanced design and operation. The screen’s unique motion ensures that particles are efficiently moved across the mesh, allowing for rapid separation.

- Minimal Blockage: The design minimizes the chances of material clogging or buildup on the screen surface, ensuring smooth operation.

- Precise Classification: The system’s vibrating motion guarantees that even small and fine particles are effectively separated.

2. Flexibility for Various Applications

The rotary vibrating screen’s ability to screen and filter a wide range of materials makes it an indispensable tool in numerous industries. It can be used for:

- Powders: Screening materials such as pharmaceutical powders, chemical powders, and food ingredients.

- Liquids: Filtering liquids such as juices, oils, slurries, and chemical solutions.

- Sticky Materials: Effectively screening and filtering sticky or viscous materials that other types of screens may struggle with.

3. Adjustable Vibration Settings

One of the key features of the rotary vibrating screen is its adjustable vibration frequency and amplitude. This flexibility allows operators to optimize the screen for different materials and requirements.

- Customizable for Specific Needs: Operators can adjust the vibration to suit the material being processed, ensuring optimal performance for each unique application.

- Gentle Handling: For sensitive materials that require delicate handling, the vibration can be set to a lower frequency to prevent particle breakage or damage.

4. Multi-Layer Design for Multiple Classifications

The ability to use multiple layers of screen mesh is one of the most significant advantages of rotary vibrating screens. This multi-layer design enables simultaneous separation of materials into different size fractions.

- Versatile Separation: The screen can be configured to classify materials into up to five different fractions, improving sorting efficiency.

- High Productivity: The multi-layer design increases throughput by allowing the separation of multiple sizes at once, reducing overall processing time.

5. Low Maintenance and Easy Cleaning

Rotary vibrating screens are known for their low maintenance requirements. The simple structure and high durability of the machine reduce the need for frequent repairs or parts replacement, which helps lower operational costs.

- Easy to Clean: The screen’s design allows for easy disassembly and cleaning, which is essential for applications in industries like food and pharmaceuticals where hygiene is crucial.

- Long-Term Durability: The robust construction ensures the equipment’s longevity, even under continuous operation.

Applications Across Different Industries

The rotary vibrating screen finds applications in a wide array of industries due to its ability to handle a range of materials efficiently.

1. Pharmaceutical Industry

In the pharmaceutical industry, precise screening and filtering are vital for ensuring the quality and consistency of powdered substances. Rotary vibrating screens are used to sieve powders and filter liquids to ensure that the ingredients meet the required specifications.

2. Food Processing

In food processing, the rotary vibrating screen is used for sifting flour, powdered spices, and other ingredients. It also plays a crucial role in liquid filtration, such as for juices, oils, and sauces, ensuring that the final product is clean and free from contaminants.

3. Chemical Industry

The chemical industry benefits from rotary vibrating screens for separating or sorting various powders and granules. These screens also provide efficient filtration of chemical suspensions and slurries to meet high industry standards.

4. Recycling and Wastewater Treatment

Rotary vibrating screens are used in wastewater treatment for filtering and separating solids from liquids, as well as in recycling operations for sorting materials such as plastics, glass, and metals.

5. Mining and Metallurgy

In the mining and metallurgy industries, rotary vibrating screens are employed to separate and sort various ore and metal powders. Their ability to handle fine particles makes them essential in operations that require precise classification.