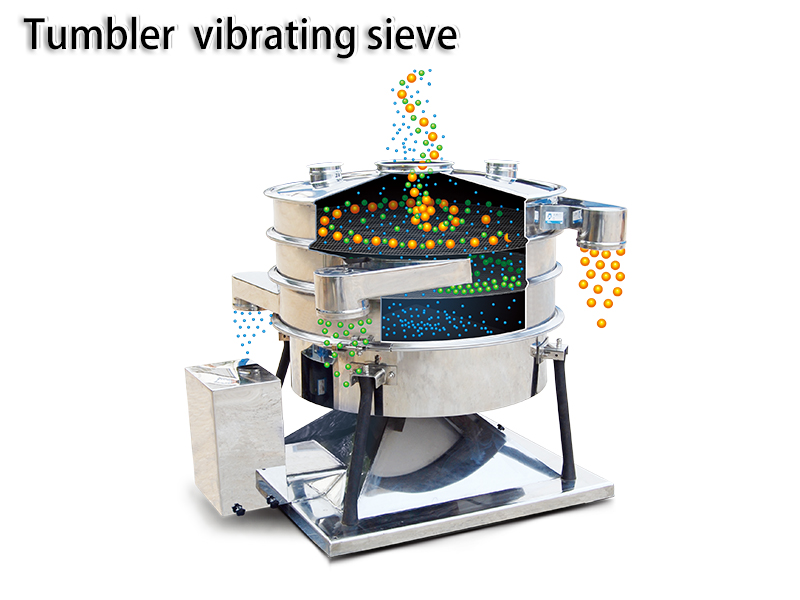

When it comes to precision screening of glass beads, achieving accurate particle classification is essential for ensuring product quality and efficiency. Our Tumbler Vibrating Screen is designed to provide superior performance in screening glass beads, offering high-capacity, multi-layered separation while maintaining gentle handling to prevent particle damage.

With the ability to classify up to six different particle sizes in a single operation, our tumbler screeners offer exceptional efficiency, flexibility, and reliability. Whether you're processing small or large volumes, our equipment can be customized to meet your specific production needs.

Key Features of Our Tumbler Vibrating Screen for Glass Beads

1. Multi-Layer Screening for Precise Particle Classification

- Our tumbler vibrating screen can effectively separate glass beads into six different particle sizes, ensuring high-precision classification.

- The multi-layered design allows for greater flexibility, accommodating different grading requirements within a single screening operation.

- Small models can be equipped with up to 4 screening layers, while large models support 5 layers for enhanced efficiency.

2. Wide Range of Sizes to Suit Your Needs

- We offer various screen body diameters ranging from 600mm (24 inches) to 2600mm (104 inches), making it easy to find a solution that fits your production scale and space constraints.

- Whether you need a compact, space-saving unit for a laboratory or a high-capacity industrial system, we have a model that suits your requirements.

3. High-Capacity Output – Up to Double the Productivity

- For single-size grading, our advanced technology allows for double or even higher throughput on the same machine, maximizing efficiency.

- By optimizing vibration patterns and motion trajectories, our tumbler vibrating screen ensures higher screening capacity compared to traditional screening methods.

4. Customizable Configurations for Maximum Efficiency

- We provide 5 to 6 grading groups, allowing for precise multi-stage separation to meet varied production needs.

- Users can adjust screening parameters, vibration amplitude, and mesh size to achieve the best separation results.

5. Gentle Screening to Protect Glass Beads

- The unique tumbler motion mimics hand-sieving techniques, ensuring gentle and efficient separation without causing damage or deformation to fragile glass beads.

- This makes our tumbler vibrating screen ideal for industries requiring high-quality, undamaged particle output.

Ideal Applications for Glass Bead Screening

Our Tumbler Vibrating Screen is widely used in industries that require high-precision grading and efficient material separation, including:

✔ Glass Industry – Grading glass beads for various industrial applications, coatings, and reflective road marking materials.

✔ Abrasives & Polishing Media – Separating different grades of glass beads used in surface finishing, blasting, and polishing.

✔ Cosmetics & Coatings – Ensuring precise bead size distribution for makeup and industrial coatings.

✔ Advanced Manufacturing – Classifying microspheres used in scientific research, electronics, and medical applications.

Why Choose Our Tumbler Vibrating Screen?

🔹 High Precision Screening – Capable of separating up to six particle sizes in a single pass.

🔹 Large Screening Diameter – Available in 600mm to 2600mm to suit different production capacities.

🔹 Multi-Layer Design – Small models with up to 4 layers and large models with up to 5 layers for maximum efficiency.

🔹 Increased Throughput – Double or even higher productivity for single-size grading applications.

🔹 Customizable Solutions – Adjustable configurations for specific industry needs.

🔹 Gentle Tumbling Motion – Prevents damage and maintains bead integrity.

Upgrade Your Screening Process Today!

If you're looking for a high-efficiency, customizable, and gentle screening solution for glass beads, our Tumbler Vibrating Screen is the perfect choice. Designed for precision separation and high output, our equipment will help you optimize your production process while maintaining the highest product quality.