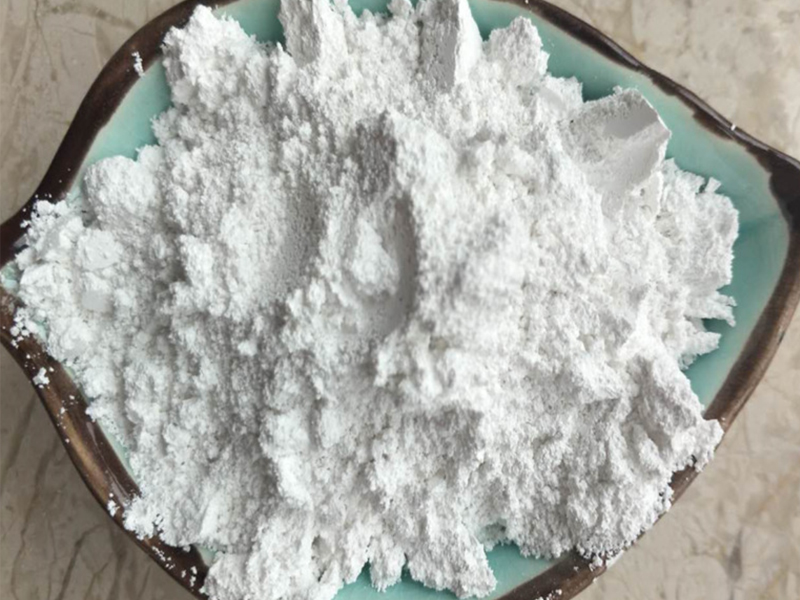

In industries such as construction, agriculture, and manufacturing, the screening of materials like gypsum powder is crucial for ensuring the quality and consistency of the final product. The ability to separate fine particles from larger ones quickly and efficiently is a key factor in optimizing production processes. The Linear Vibrating Screen is designed to provide high-performance screening, offering precise separation, high throughput, and enhanced durability—making it the perfect solution for gypsum powder screening.

1. Stainless Steel Linear Vibrating Screen

The Stainless Steel Linear Vibrating Screen is an advanced screening solution tailored for the efficient separation and classification of gypsum powder. Made from high-quality stainless steel, this vibrating screen offers durability, corrosion resistance, and long service life, which are essential for handling gypsum, a material known for its abrasiveness and tendency to accumulate moisture. This vibrating screen uses linear vibration technology, which ensures a smooth and consistent screening process with minimal wear and tear.

With its precise screening capabilities, high capacity, and low maintenance requirements, the Linear Vibrating Screen provides an ideal solution for businesses in the gypsum powder production industry.

2. Key Features and Advantages

(1) High Screening Precision

The Linear Vibrating Screen ensures precise separation of gypsum powder based on particle size. With its linear motion, the screen evenly distributes the material, allowing fine particles to pass through the mesh while retaining larger particles. This precise classification is essential for producing high-quality gypsum powder suitable for use in plasterboard production, cement manufacturing, or as a fertilizer in agriculture.

(2) Durable Stainless Steel Construction

One of the most significant advantages of this vibrating screen is its use of stainless steel in construction. Stainless steel offers superior resistance to corrosion, rust, and abrasion, which is particularly important in gypsum powder screening, as gypsum can be highly abrasive and reactive with water. The stainless steel components also help maintain the machine's structural integrity over time, ensuring long-lasting performance and minimizing the need for frequent repairs or replacements.

(3) High Throughput Capacity

The Linear Vibrating Screen is designed to handle high volumes of gypsum powder efficiently. Whether the application requires processing small batches or large-scale operations, this vibrating screen delivers optimal throughput without compromising screening efficiency. Its high capacity ensures that production lines operate at maximum efficiency, helping businesses meet growing demand while maintaining product quality.

(4) Minimal Maintenance and Easy to Clean

Gypsum powder can be prone to sticking to surfaces due to its fine nature and moisture retention. However, the Linear Vibrating Screen is designed with easy-to-clean surfaces that help prevent build-up and ensure smooth operation. Its simple structure and robust design minimize the need for frequent maintenance, allowing operators to spend less time on upkeep and more time focusing on production.

(5) Efficient Vibration Mechanism

The linear vibration mechanism ensures that the gypsum powder is evenly distributed across the screen deck, enhancing the separation process. The vibration helps to move the particles in a controlled manner, reducing material clogging and preventing the screen from becoming obstructed. This results in a more efficient screening process, ensuring higher throughput and fewer product rejects.

(6) Adjustable Screening Parameters

The Stainless Steel Linear Vibrating Screen is designed with flexibility in mind. Operators can adjust parameters such as vibration amplitude, frequency, and mesh size to customize the machine for specific gypsum powder characteristics. This adjustability allows businesses to fine-tune the separation process for different grades or particle sizes, ensuring that the final product meets specific requirements.

3. How the Stainless Steel Linear Vibrating Screen Works

The Linear Vibrating Screen works by utilizing a vibration motor to generate linear motion on the screen surface. Gypsum powder is fed into the machine from one side, and as the material passes over the mesh, the linear vibration causes the particles to move forward. Fine particles pass through the mesh, while larger particles remain on the surface. The screened gypsum powder is then collected on the other side for further processing or packaging.

The linear motion ensures that the material flows smoothly and evenly across the screen, preventing clogging and improving the efficiency of the separation process. This ensures that gypsum powder is accurately classified into different grades, depending on the specific application.

4. Applications in Gypsum Powder Production

The Linear Vibrating Screen is used in various applications within the gypsum powder industry, where precise and efficient screening is essential:

- Plasterboard Manufacturing: In the production of plasterboard, gypsum powder needs to be accurately sized to ensure consistency and quality. The linear vibrating screen efficiently removes oversized particles, ensuring uniformity in the powder used for making boards.

- Cement Industry: Gypsum powder is a key ingredient in cement manufacturing, where it is used to control the setting time of the cement. The vibrating screen ensures that only the correctly sized powder is used in production, maintaining the quality of the final product.

- Agriculture: Gypsum powder is often used as a soil conditioner in agricultural applications. Proper screening ensures that only the desired particle sizes are used, promoting better soil aeration and improving crop yield.

- Water Treatment: Gypsum is used in water treatment processes to remove impurities. The linear vibrating screen ensures that the gypsum used is consistently sized, ensuring its effectiveness in these applications.

5. Why Choose the Stainless Steel Linear Vibrating Screen?

For businesses in the gypsum powder industry, the Linear Vibrating Screen offers numerous benefits:

- Durability and Longevity: The high-quality stainless steel construction ensures that the machine can withstand the abrasive and corrosive nature of gypsum powder, providing long-term service.

- High Throughput: The vibrating screen’s high-capacity design allows for the efficient processing of large volumes of gypsum powder, making it suitable for both small-scale and large-scale operations.

- Customization: With adjustable parameters, the screen can be tailored to meet the specific requirements of different gypsum powder grades or particle sizes.

- Low Maintenance Costs: The simple structure, combined with the easy-to-clean surfaces, minimizes maintenance requirements and operational downtime.

- Efficient and Precise Separation: The linear vibration mechanism ensures accurate screening, improving the quality of the final product and reducing waste.