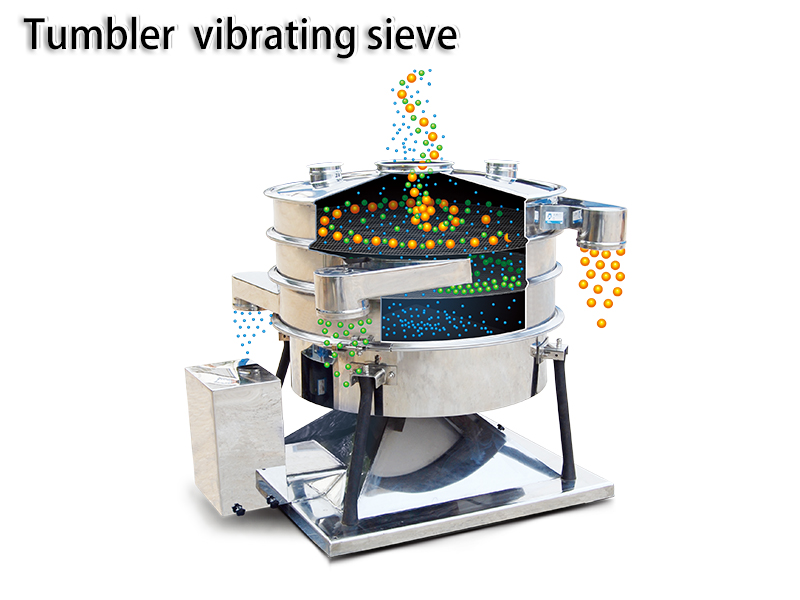

In material processing industries, some products require gentle handling to prevent particle breakage and maintain their structural integrity. Traditional vibrating screens may generate excessive force, leading to unwanted material degradation. The Tumbler Vibrating Screen (GFBD) is specifically designed to replicate the natural hand-sieving motion, ensuring a smooth and controlled screening process. This makes it an ideal solution for applications where particle preservation is critical, such as spray-dried coffee granules, pharmaceutical powders, milk powder, and metal powders.

Gentle Processing with Hand-Sieving Motion

Unlike conventional vibrating screens that rely on high-frequency vibrations, the Tumbler Vibrating Screen mimics the manual sieving process, providing a soft, rolling motion that efficiently separates materials while minimizing impact. This motion is particularly beneficial for delicate, friable, and brittle materials, as it:

✔ Prevents particle breakage, maintaining product quality.

✔ Ensures uniform material flow, reducing product loss.

✔ Provides high-efficiency screening, increasing throughput.

This unique motion makes the tumbler vibrating screen the preferred choice for industries that handle sensitive materials requiring precision and care.

Optimized Material Flow for Superior Separation

The Tumbler Vibrating Screen features an advanced material movement mechanism that enhances the screening process.

- Centralized Feed for Even Distribution

- Material enters the screen at the center, where it is gently dispersed outward in a spiral motion.

- This gradual outward expansion prevents material buildup and ensures uniform exposure to the screening surface.

- Helical Motion for Efficient Classification

- As materials move outward, the screen generates a helical movement, guiding the particles along the screening surface.

- This allows for high-precision classification, effectively separating fine and coarse materials.

- Vertical Acceleration for Maximum Screening Efficiency

- The vertical acceleration gradually increases, forcing smaller particles to efficiently pass through the screen mesh.

- This ensures high screening accuracy while maintaining a low-impact process, preserving particle integrity.

Ideal for a Wide Range of Applications

The Tumbler Vibrating Screen is highly versatile and widely used in industries that require high-precision screening without compromising material quality. Key applications include:

- Food Industry – Screening of spray-dried coffee granules, milk powder, starch, and spices.

- Pharmaceutical Industry – Gentle classification of powdered medicines and active ingredients.

- Chemical Industry – Screening of fine powders and specialty chemicals.

- Metal Powders – Efficient classification of fine metal particles and alloy powders.

Advantages of the Tumbler Vibrating Screen

✅ Gentle Material Handling – Prevents particle breakage, preserving material properties.

✅ Highly Efficient Screening – Achieves accurate classification with minimal material loss.

✅ Optimized Material Flow – Spiral motion enhances screening efficiency.

✅ Customizable for Various Needs – Can be configured for different mesh sizes and material properties.

✅ Energy-Efficient & Low Maintenance – Reduces operating costs while ensuring long-term performance.