In today’s fast-paced and highly competitive industrial landscape, the need to optimize production processes and reduce operational costs has never been greater. One often overlooked, but essential component in achieving these objectives is the screen mesh used for material separation, filtration, and sorting. Gaofu screen mesh has emerged as a leader in providing solutions that not only enhance operational efficiency but also effectively save both time and cost for businesses across various industries.

From reducing downtime to increasing product quality, Gaofu’s screen mesh solutions are designed to offer substantial improvements in screening performance and overall productivity. Let’s dive deeper into how Gaofu screen mesh can be a game-changer for your business, helping you streamline operations while maximizing cost-effectiveness.

Time-Saving Benefits of Gaofu Screen Mesh

1. Reduced Downtime with Durable Materials

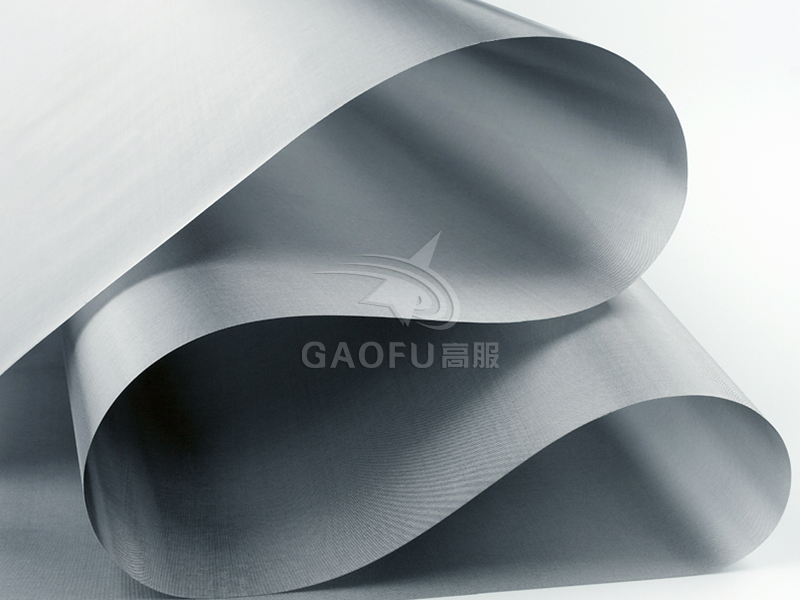

One of the most significant contributors to production inefficiency is equipment downtime, whether due to screen mesh failure or the need for frequent replacements. Gaofu screen mesh is engineered with high durability in mind, providing robust and long-lasting performance in the most demanding environments.

Thanks to the high-quality materials used, such as stainless steel or polyurethane, Gaofu mesh resists abrasion and wear even when processing coarse, abrasive materials. This extended service life reduces the need for frequent maintenance or mesh replacements, ensuring your equipment remains operational for longer periods.

As a result, production processes experience fewer interruptions, allowing businesses to maintain consistent output and increase overall throughput. Less downtime equates to a more efficient and cost-effective production cycle, ultimately saving significant time in your operation.

2. Faster Replacement and Setup Times

When screen mesh needs to be replaced or maintained, the process can often be time-consuming and disruptive to the production line. With Gaofu’s easy-to-install and user-friendly design, mesh changes are faster and more efficient. The simple installation process allows for quick replacements without requiring extensive downtime, minimizing disruption and ensuring your equipment returns to full operation with minimal delays.

By reducing the time spent on setup or maintenance, your production can continue smoothly, and the impact on your overall timeline is greatly minimized.

Cost-Saving Benefits of Gaofu Screen Mesh

1. Reduced Maintenance and Replacement Costs

While some businesses may initially hesitate to invest in high-quality screen mesh, Gaofu’s durable solutions quickly prove to be a cost-effective choice. With a longer lifespan and reduced wear, businesses experience fewer replacements and lower maintenance needs. This means that you can significantly reduce long-term operational expenses tied to mesh repairs or replacements.

Additionally, less maintenance means lower labor costs and fewer parts to replace, all of which contribute to direct savings over time. The initial investment in Gaofu screen mesh often pays for itself in cost savings due to its extended durability and improved efficiency.

2. Improved Material Yield and Product Quality

Gaofu screen mesh is designed for precision screening, ensuring that materials are properly separated and sorted to the required specifications. When materials are accurately separated, the risk of reprocessing or material wastage is minimized. This results in higher yields of usable material, making your production process much more efficient and cost-effective.

Furthermore, Gaofu’s mesh enhances the consistency and quality of the final product by ensuring that only the correct material passes through the mesh, which reduces the need for rework or quality checks. With fewer defective products or return issues, you can save money on labor, time, and resources, ultimately contributing to improved profitability.

3. Energy Efficiency

Gaofu screen mesh is designed not only for durability and performance but also for energy efficiency. The materials used ensure optimal flow rates, requiring less energy to operate the screening systems. This helps reduce the overall energy consumption in your operation. By cutting down on energy costs, you can make your production processes even more economical.

Gaofu Screen Mesh in Action: Real-World Applications

Gaofu screen mesh is versatile and finds applications in various industries where cost-efficiency and time-saving are critical. Whether you’re in the chemical, food, mining, or pharmaceutical sectors, Gaofu mesh can be customized to meet your specific needs.

- In the mining industry, Gaofu screen mesh helps separate valuable materials from waste efficiently, preventing costly downtime while ensuring that only high-quality ore is processed.

- In food production, where hygiene and precision are essential, Gaofu mesh offers accurate separation while maintaining strict standards for food safety and cleanliness.

- In pharmaceuticals, where consistency and purity are paramount, Gaofu screen mesh ensures accurate particle size separation, minimizing wastage and reprocessing, which leads to substantial savings.