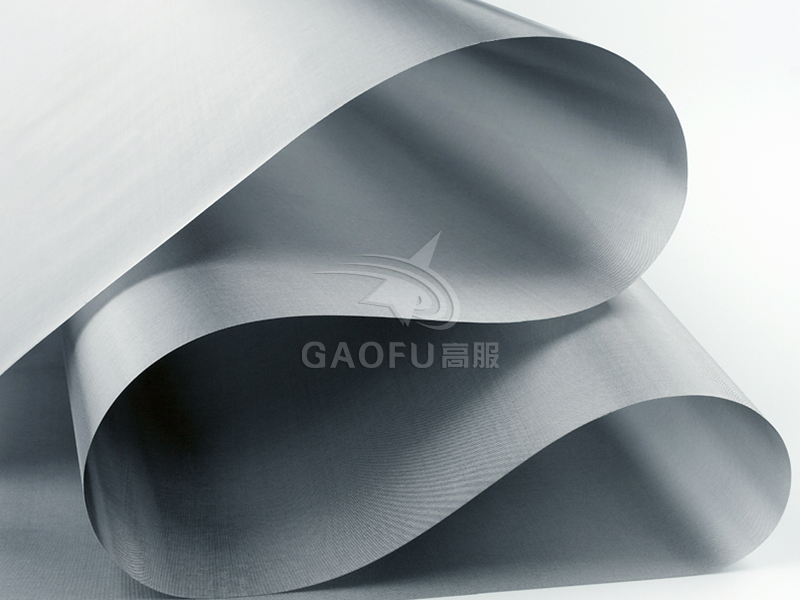

Twill weave mesh, a specialized form of woven metal mesh, is renowned for its durability and adaptability across various industries. Due to its ability to withstand extreme environmental conditions, such as acidic and alkaline environments, it is highly sought after for screening, filtration, and separation tasks. This robust mesh finds extensive use in industries such as petroleum, chemical fiber production, and electroplating, where its resilience and high performance are crucial. Below, we explore the key applications of twill weave mesh and the benefits it offers to different industries.

1. Twill Weave Mesh in Acidic and Alkaline Environments

One of the most significant advantages of twill weave mesh is its resistance to acidic and alkaline conditions. This makes it the ideal choice for industries that deal with harsh chemicals and corrosive substances. The mesh’s material can withstand aggressive environmental factors without degrading, which ensures longevity and reliability in demanding applications.

In these environments, other types of mesh might corrode or lose their functionality, but twill weave mesh maintains its structural integrity. Whether used for filtration or screening, it offers exceptional resistance to both acidic and alkaline environments, ensuring that the filtration or screening processes remain effective and consistent over time.

2. Petroleum Industry: Drilling and Mud Screening

In the petroleum industry, one of the most common applications for twill weave mesh is in the form of mud screens used in drilling operations. During the extraction of oil and gas, drilling mud is used to lubricate the drill and carry debris to the surface. Twill weave mesh plays a crucial role in screening drilling mud to remove larger particles and ensure the cleanliness and efficiency of the process.

Twill weave mesh provides an excellent solution for filtering and separating solids from the drilling fluid, maintaining the fluid’s consistency and optimizing the drilling performance. The mesh's high tensile strength and resistance to wear make it suitable for these high-pressure, abrasive environments. The ability to handle large volumes of fluid while maintaining efficiency gives petroleum companies a reliable tool for smooth operation and cost-effective performance.

3. Chemical and Fiber Industry: Screening and Filtration

In the chemical and fiber industries, twill weave mesh is primarily used for screening and filtration applications. Chemical processes often involve highly corrosive substances, and the mesh needs to maintain resistance to chemicals while also offering precise filtration. Twill weave mesh provides just that, ensuring that precise separation of materials is achieved without compromising the structural integrity of the mesh.

Twill weave mesh serves as an ideal solution for filtration systems that separate fine particles from liquids or gases, which is essential in industries such as textile production and chemical processing. By using high-quality mesh, these industries can ensure that their production processes are efficient, clean, and safe, all while maintaining high levels of product purity.

Additionally, in the chemical fiber industry, the mesh is used to filter chemicals during production processes, ensuring that contaminants are removed effectively, leading to high-quality finished products. Its resistance to abrasion ensures long service life, making it a highly effective and cost-efficient option for this industry.

4. Electroplating Industry: Acid Wash Screens

The electroplating industry is another sector where twill weave mesh proves to be invaluable. It is commonly used as acid wash screens, which play a crucial role in the cleaning and preparation of metal surfaces before plating. In electroplating, the process involves exposing metal parts to acidic solutions to remove contaminants, and this process can be quite harsh on the materials used for filtration.

Twill weave mesh is perfectly suited for this application because of its high resistance to acids. The mesh does not degrade or corrode, even when exposed to strong acids used in the electroplating process. Its structural integrity ensures that it can withstand the intense chemical reactions and mechanical stresses associated with acid washing, while providing the filtration efficiency needed to achieve clean, well-prepared metal parts.

The mesh’s ability to resist damage from harsh chemicals and its excellent filtering capacity make it a go-to material for acid washing processes. Its use helps reduce downtime, increase productivity, and maintain safety in the electroplating industry.

5. Other Industrial Applications

Beyond the petroleum, chemical, and electroplating industries, twill weave mesh has a broad range of applications across many other sectors. These include:

- Food and beverage industry: For precise separation of solid particles from liquids or gases, ensuring product purity.

- Mining industry: In the screening of minerals and ores, where mesh needs to withstand abrasive conditions while separating different particle sizes.

- Pharmaceutical industry: For ensuring the separation of powders and granular materials, guaranteeing product quality and consistency.

No matter the industry, twill weave mesh provides a cost-effective, durable, and high-performance solution for filtration and screening.