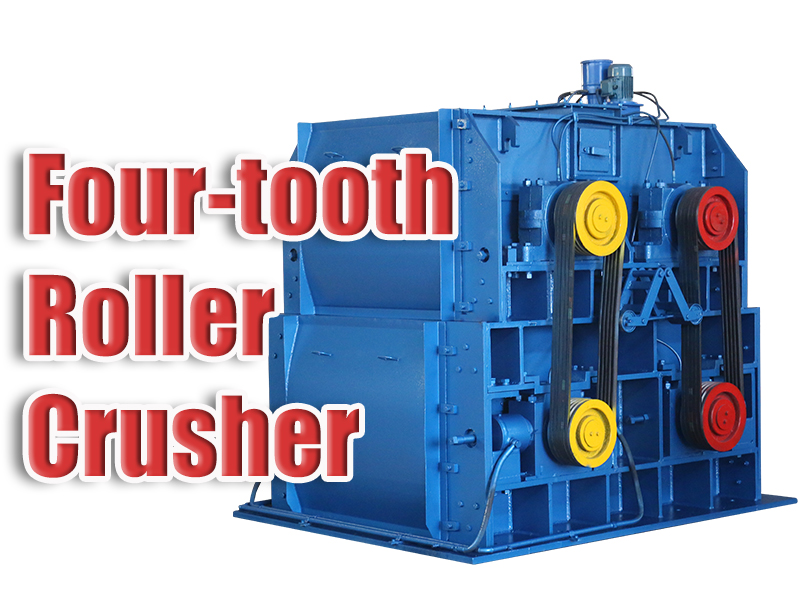

The four-tooth roller crusher, also known as the coal crusher, is a robust and efficient machine designed to crush various materials, particularly in the coal and mining industries. Its advanced features, such as low over-crushing rates and optimal particle size distribution, make it an indispensable tool in material processing. In this article, we will explore the key advantages of the four-tooth roller crusher and highlight its effectiveness in producing uniformly sized products with minimal energy consumption.

Efficient and Precise Crushing

The four-tooth roller crusher employs a combination crushing technique, which allows for instantaneous and rigid crushing of materials. This feature helps prevent excessive grinding and ensures that the particle size of the crushed material is precise and consistent. The crusher has a low re-crushing rate, meaning it produces fewer fine particles during operation, which is especially beneficial for industries requiring a certain range of particle sizes.

The roller crusher uses four teeth that work together to break down materials effectively. The sharp teeth provide a powerful crushing force that enables quick and efficient processing of materials like coal, ores, and other medium-hard substances. The result is a uniform discharge, ensuring that the material is ready for the next stage of processing.

Uniform Material Distribution and Longer Wear Life

One of the standout features of the four-tooth roller crusher is its vibrating coal feeding system, which ensures that the material is uniformly distributed across the crusher’s teeth. This uniformity in material distribution helps prevent uneven wear on the teeth and reduces the risk of tooth plate imbalance. Over time, this leads to a longer operational life for the machine’s critical components, particularly the tooth plates.

The vibrating feeder serves two main purposes: it ensures a steady flow of material into the crusher, and it minimizes uneven wear on the tooth plates, helping the crusher maintain its efficiency over time. The uniform distribution also prevents clumping or congestion, which could otherwise reduce the crusher’s performance.

Environmental Benefits: Energy Efficiency and Low Pollution

The four-tooth roller crusher is designed with environmental responsibility in mind. Its energy-efficient design minimizes power consumption while still achieving high crushing capacity. This low-energy consumption helps reduce operational costs and supports sustainable industrial practices.

In addition, the crusher generates minimal dust and noise, making it a low-pollution machine that complies with modern environmental regulations. The dust suppression system and low noise output make it suitable for installation in locations where environmental concerns are a priority, such as urban areas, mining operations, and coal processing plants.

Adjustable Feed and Discharge Sizes

The four-tooth roller crusher is highly adaptable, offering flexibility in its operation. The feed size is adjustable, with a maximum input size of up to 300mm, allowing the crusher to handle various types of raw materials. Meanwhile, the discharge size is adjustable to as fine as 10mm, making it suitable for various industries that require finely crushed material.

The adjustable crushing ratio is one of the key selling points of this machine. The one-time crushing ratio can reach up to 50, which means it can reduce the size of large feed material significantly in a single pass. This is a huge advantage in industries where rapid and efficient material size reduction is required.

Self-Adjusting for Non-Breakable Materials

The four-tooth roller crusher is equipped with a self-adjusting mechanism that provides added protection when handling non-breakable or flexible materials. When materials such as wood, non-magnetic alloys, or rubber enter the crushing chamber, the two roller teeth can automatically retract and release the material without causing damage to the crusher.

This self-adjusting mechanism prevents unnecessary wear and tear on the machine and ensures that the crusher operates smoothly even when encountering unexpected materials. It also helps reduce the risk of blockages and ensures uninterrupted operation, which is essential for industries that require continuous production without downtime.

High Crushing Efficiency

The four-tooth roller crusher is known for its high crushing efficiency. The combination of its precise teeth design, vibrating feeder system, and adjustable feed and discharge sizes enables the machine to handle large quantities of materials in a short amount of time, while still maintaining the desired product quality. The low over-crushing rate ensures that the material is processed quickly without generating excess fines.

This makes the four-tooth roller crusher ideal for industries that require high throughput and consistent quality, such as the coal, mining, and chemical industries. The machine’s performance is particularly advantageous in high-volume operations where maintaining production efficiency is a priority.