When processing protein particles, standard screening equipment often faces challenges such as pseudo-agglomeration (false clumping), screen clogging, and low throughput.

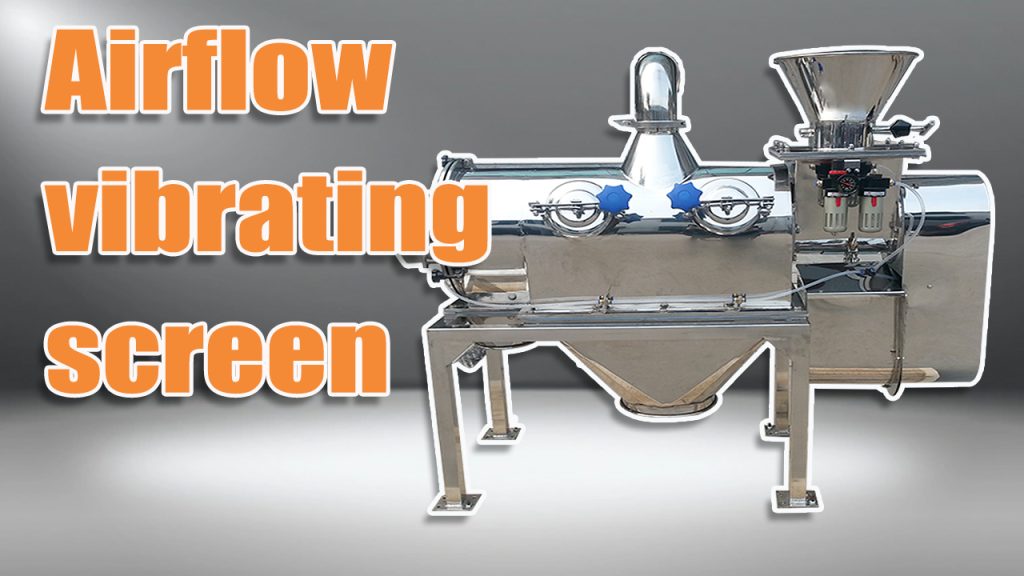

Our Airflow Vibrating Sieve is specifically designed to address these challenges, offering high-speed, clog-free screening with an innovative cyclone air-washing mechanism that keeps the mesh clean and ensures continuous operation. Whether used in food, pharmaceutical, or chemical industries, this advanced screening solution provides superior performance, reliability, and efficiency.

Key Features of Our Airflow Vibrating Sieve for Protein Particle Screening

1. Efficient Screening of Protein Particles

- Our airflow vibrating sieve is engineered to quickly and efficiently separate protein particles, ensuring high-precision classification and uniform product quality.

- The high-speed airflow inside the machine allows for rapid material dispersion, improving screening efficiency and preventing blockages.

2. Breaks Up Pseudo-Agglomeration for Improved Screening

- One of the biggest challenges in protein particle processing is pseudo-agglomeration, where fine particles clump together, reducing screening accuracy.

- Our airflow sieve has a built-in de-agglomeration function, which effectively breaks up false clumps and ensures that individual particles are evenly distributed for precise separation.

3. Self-Cleaning Mesh for Continuous Operation

- Unlike traditional vibrating screens that often suffer from mesh clogging, our airflow vibrating sieve features a cyclone air-washing system that automatically cleans the screen during operation.

- This feature minimizes downtime, increases throughput, and ensures long-lasting efficiency without frequent manual maintenance.

4. Advanced Cyclone Airflow Technology

- The rotating airflow inside the sieve effectively accelerates material movement, allowing even the finest protein particles to pass through the screen without sticking or clogging.

- This makes it ideal for ultra-fine powders and ensures high-speed, high-capacity screening.

5. High-Capacity & Customizable Design

- Our airflow vibrating sieve can be customized to handle various batch sizes and screening requirements, making it suitable for both small-scale laboratory use and large-scale industrial production.

- Available in multiple mesh sizes, it can be tailored to meet specific industry needs.

Ideal Applications for Protein Particle Screening

Our Airflow Vibrating Sieve is widely used in industries that require high-precision particle classification, including:

✔ Food Processing – Screening protein powders and food additives to maintain purity and consistency.

✔ Pharmaceuticals – Ensuring precise particle separation for nutritional supplements and medical formulations.

✔ Chemical Industry – Separating fine protein-based powders for biotechnology and chemical processing.

✔ Agriculture & Animal Feed – Classifying protein-rich feed components for better quality control.

Why Choose Our Airflow Vibrating Sieve?

🔹 Efficient Protein Particle Screening – Ensures high-speed and precise classification.

🔹 De-Agglomeration Function – Breaks up pseudo-clumps for better separation.

🔹 Self-Cleaning System – The cyclone airflow technology keeps the mesh clear, reducing downtime.

🔹 High-Capacity & Customizable – Available in various sizes to fit different production needs.

🔹 Gentle & Non-Damaging – Maintains the integrity of delicate protein particles.

Optimize Your Protein Screening Process Today!

If you're looking for a high-efficiency, clog-free, and precision screening solution for protein particles, our Airflow Vibrating Sieve is the perfect choice. With its self-cleaning mechanism and de-agglomeration function, it ensures higher productivity, reduced waste, and superior product quality.