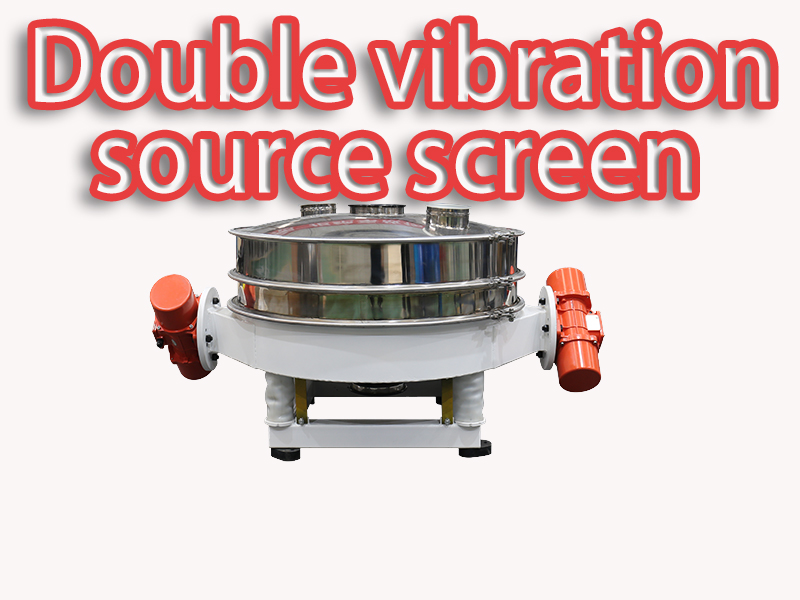

The Double Vibration Source Screen, also known as a direct discharge vibrating screen, is a highly efficient screening device widely used in powder production lines for impurity removal and material loosening. This screening equipment utilizes either a single or double horizontal vibration motor as its excitation source, generating an elliptical motion trajectory of materials on the screen surface. The unique design and working mechanism of this screen make it an essential tool in industries such as food processing, chemicals, pharmaceuticals, and mining, where precise and efficient screening is required.

With its durable structure, customizable screen options, and strong vibration intensity, the Double Vibration Source Screen ensures high processing efficiency, reduced material clogging, and optimized screening performance.

Structural Features of the Double Vibration Source Screen

This screening equipment is composed of several key components that contribute to its durability and efficiency:

1. Screen Frame

The screen frame is typically constructed using high-quality steel materials, ensuring it can withstand both the weight of materials and the stress generated by vibrations. Its reinforced structure enhances the machine’s stability, prolonging its operational lifespan.

2. Screen Mesh

The screen mesh is a crucial component that determines the precision of the screening process. It is available in various materials and aperture sizes, allowing customization based on the specific material being processed. The high-strength and wear-resistant mesh ensures long-lasting performance and minimal clogging.

3. Vibration Motor

The vibration motor serves as the power source of the screening machine. It is available in single-motor or dual-motor configurations, depending on the required vibration intensity and processing capacity. The unique motor installation design induces linear vibration, which efficiently moves materials across the screen surface.

Working Principle of the Double Vibration Source Screen

The operating mechanism of this screening machine ensures fast and efficient material separation:

- Vibration Activation – Once the vibration motor is activated, it generates a linear excitation force that causes the screen body to vibrate perpendicular to the screen surface.

- Material Movement – Under the influence of vibration, materials move in a straight-line trajectory along the screen surface.

- Separation Process –

- Fine particles that are smaller than the screen openings pass through the mesh and are collected as undersized material.

- Larger particles that cannot pass through the mesh continue moving forward and exit through the discharge outlet, completing the screening process.

This efficient screening mechanism allows for rapid material classification, impurity removal, and uniform particle distribution.

Key Advantages of the Double Vibration Source Screen

1. High Screening Efficiency

The powerful dual vibration motor design enhances the screening speed and separation accuracy, ensuring maximum efficiency in processing various materials.

2. Direct Discharge Design for Fast Processing

The straight-line material flow minimizes retention time within the screen, ensuring:

- Faster material throughput,

- Reduced material accumulation,

- Higher product purity.

This feature makes the Double Vibration Source Screen ideal for high-volume production lines.

3. Customizable Screen Mesh for Different Materials

With various screen mesh materials and aperture sizes available, this equipment can be tailored to suit different industry requirements. This ensures optimal performance across various material types, from fine powders to coarse granules.

4. Versatile Application Across Multiple Industries

The Double Vibration Source Screen is widely used in several industrial sectors, including:

1. Food Processing Industry

- Screening of flour, starch, milk powder, coffee powder, spices, sugar, and other food ingredients to remove impurities and ensure uniform particle distribution.

- Helps meet hygienic and quality standards in food production.

2. Chemical Industry

- Used for particle size classification of plastic granules, carbon black, calcium carbonate powder, and other chemical compounds.

- Enhances product consistency and purity by efficiently separating fine and coarse particles.

3. Pharmaceutical Industry

- Essential for screening pharmaceutical granules and powders to ensure uniform size distribution and impurity-free formulations.

- Meets strict regulatory standards for pharmaceutical manufacturing.

4. Mining and Metallurgy Industry

- Used for the preliminary classification of ores, minerals, and metallic powders before further processing.

- Increases processing efficiency by reducing unwanted fine particles early in the workflow.

5. Simple Structure and Low Maintenance

- User-friendly design allows for easy installation and operation.

- Minimal moving parts reduce wear and tear, ensuring long service life.

- The quick-release screen frame allows for fast screen changes, minimizing downtime.

6. Energy-Efficient and Cost-Effective

The optimized vibration mechanism reduces energy consumption, making it a cost-effective solution for large-scale production facilities.