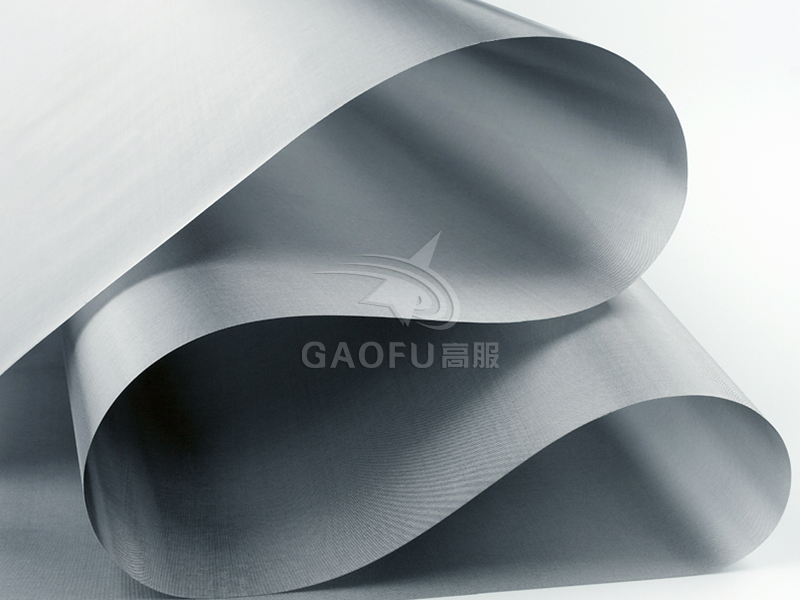

The twilled weave fine mesh is a high-quality metallic mesh structure used for various industrial applications, such as screening, filtration, dewatering, and sludge separation. Known for its exceptional performance and durability, this mesh has become an indispensable tool in numerous industries, including mining, chemicals, food processing, pharmaceuticals, and environmental management.

High Strength and Rigidity for Demanding Applications

One of the standout features of the twilled weave fine mesh is its high strength and rigidity, which are crucial for effective screening and filtration processes. This mesh is built to withstand high levels of stress, ensuring that it remains intact even under the most demanding operational conditions. With a high load-bearing capacity, this mesh can handle heavier materials and more abrasive substances without compromising performance.

The mesh's strong structural integrity allows it to be fabricated into various shapes and sizes, creating rigid screening and filtration devices that meet the specific needs of diverse industrial processes. Whether it's being used in a vibrating screen or a filtration unit, the twilled weave fine mesh consistently provides reliable results in material separation.

Superior Performance: High Screening Efficiency and Strong Tensile Strength

Manufactured using advanced welding techniques, the twilled weave fine mesh features a tightly woven structure that ensures high screening efficiency. The fine openings in the mesh are designed to filter out even the smallest particles, allowing only the desired materials to pass through while retaining unwanted impurities or debris. This makes it an ideal solution for applications that require high-precision filtering or fine particle separation.

The mesh also has strong tensile strength, making it highly resistant to deformation, even under pressure. Its ability to resist shock and stretching ensures that it maintains its shape and functionality over long periods of use, even in industries where the mesh is subjected to continuous motion or vibration. This makes the mesh especially useful for processes like dewatering and screening, where maintaining the integrity of the mesh is critical to the efficiency of the entire system.

Minimal Maintenance and Long Service Life

Another key advantage of the twilled weave fine mesh is its low maintenance requirement. Unlike many other types of mesh that require frequent adjustments or replacements, the twilled weave fine mesh is designed to be highly durable with minimal wear and tear. Its resistance to corrosion, wear, and damage from harsh chemicals or environmental factors ensures that it remains in excellent condition for extended periods.

The mesh’s long service life reduces the need for frequent replacements, translating into lower operating costs for businesses. Whether used in filtration units or screening equipment, the mesh continues to perform efficiently, helping businesses maintain smooth operations while reducing downtime and maintenance costs.

Materials of Construction: Quality and Durability

The materials used to make the twilled weave fine mesh are equally important to its performance. The mesh is typically made from high-quality stainless steel grades, including 304, 316L, and 904L, each of which offers specific advantages depending on the industry and application requirements.

- 304 Stainless Steel: Known for its corrosion resistance and durability, 304 stainless steel is commonly used in food processing, pharmaceuticals, and chemical industries where hygiene and resistance to environmental factors are important.

- 316L Stainless Steel: With its superior corrosion resistance to chloride solutions and more extreme environments, 316L is often used in marine, chemical, and pharmaceutical applications.

- 904L Stainless Steel: This high-alloy steel offers excellent resistance to acids and corrosion, making it ideal for harsh chemical environments and industries where corrosive materials are handled.

By selecting the appropriate material based on the specific needs of the operation, businesses can ensure the longevity and reliability of their twilled weave fine mesh, resulting in higher performance and lower overall costs.

Applications Across Multiple Industries

The versatility of the twilled weave fine mesh makes it suitable for a broad range of industries, each with its unique needs for screening, filtration, and separation. Some of the most common applications include:

- Mining Industry: In mining, the mesh is used for sieving ores, coal, and other bulk materials. Its high strength and resistance to abrasion make it ideal for handling rough and coarse materials.

- Food and Beverage Industry: In food processing, the mesh is often used for filtering powders, separating grains, or dewatering materials. The fine openings and corrosion resistance make it perfect for ensuring food safety and meeting strict industry standards.

- Chemical and Pharmaceutical Industries: These industries rely on high-precision filtering to separate fine powders, granules, and liquids. The twilled weave fine mesh is well-suited for these applications due to its tight weave and high resistance to corrosion.

- Environmental Management: In wastewater treatment or sludge separation, the twilled weave fine mesh is often used to separate solid waste from liquid effluents, ensuring effective filtration and cleaning processes.

- Construction and Aggregates: The mesh is also widely used in construction for sifting aggregates and gravel, ensuring that only properly sized materials are used in construction projects.