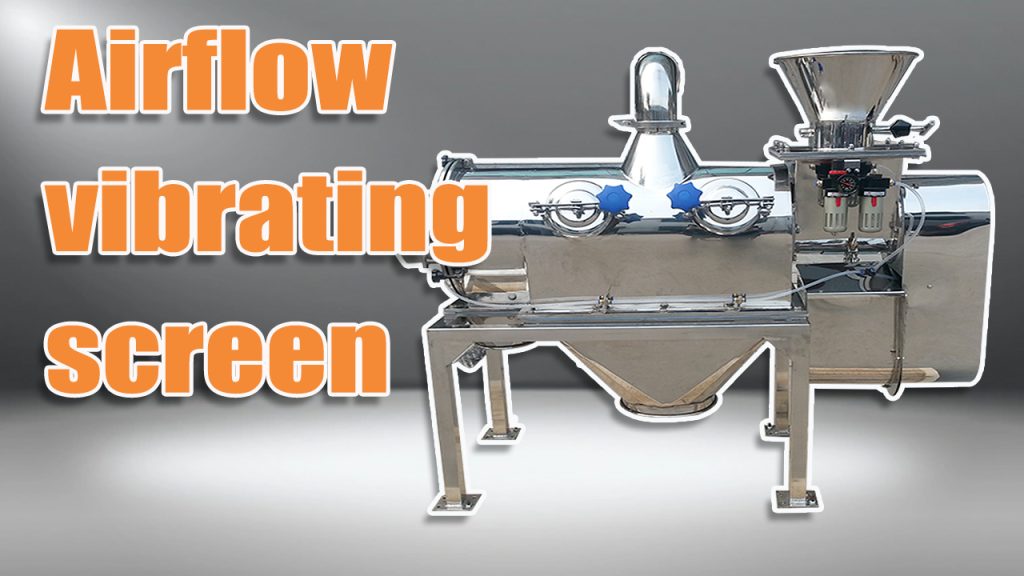

In industries that handle fine powders, such as aluminum oxide (Al₂O₃), achieving precise and efficient material separation is crucial. Traditional screening methods often face challenges such as material agglomeration, reduced efficiency, and inconsistent particle size distribution. The airflow vibrating screen is a highly efficient solution designed to break up material clumps and ensure smooth, uniform screening. This article explores the working principles, advantages, and applications of airflow vibrating screens in aluminum oxide powder screening.

How the Airflow Vibrating Screen Works

Unlike conventional vibrating screens that rely on direct mechanical vibrations to separate materials, an airflow vibrating screen integrates airflow technology with vibration to enhance screening performance. The process involves:

- High-Frequency Vibrations – The machine generates controlled vibrations that keep the aluminum oxide powder in constant motion, preventing settling and clogging.

- Airflow Dispersal – A stream of air passes through the material, effectively breaking up clumps and ensuring that the particles remain free-flowing.

- Precision Sieving – The fine powder is then passed through a mesh screen, where smaller particles are separated from larger impurities or agglomerates.

- High-Speed Processing – The combined effect of airflow and vibration significantly increases the screening speed and efficiency, making it ideal for industrial-scale operations.

Key Advantages of the Airflow Vibrating Screen for Aluminum Oxide Powder

1. Efficient Deagglomeration

One of the biggest challenges in aluminum oxide powder screening is material agglomeration. The airflow vibrating screen excels at breaking up these clumps, ensuring uniform particle distribution and improving product quality.

2. High Screening Efficiency

The combination of airflow and vibration allows for rapid and precise separation of fine particles, significantly improving throughput while maintaining accuracy.

3. Reduced Blockage and Clogging

Traditional vibrating screens often face mesh clogging issues when dealing with fine powders. The airflow mechanism prevents particles from sticking together or accumulating on the screen surface, minimizing downtime and maintenance costs.

4. Gentle Material Handling

Aluminum oxide is often used in sensitive applications such as ceramics, abrasives, and electronics. The airflow vibrating screen provides a non-destructive screening process, preserving the integrity of delicate particles.

5. Energy Efficiency

Compared to mechanical screening methods that require higher energy input, the airflow vibrating screen optimizes power usage by integrating both vibration and airflow, leading to lower operational costs.

Applications of Airflow Vibrating Screens in Aluminum Oxide Processing

The ability to efficiently screen and classify aluminum oxide powder makes airflow vibrating screens essential in various industries, including:

- Abrasives Manufacturing – Ensuring uniform particle size for grinding and polishing applications.

- Ceramic Production – Preparing high-purity aluminum oxide powders for ceramic materials.

- Metallurgical Processing – Classifying aluminum oxide for use in smelting and refining.

- Electronics Industry – Ensuring fine powder consistency for advanced electronic components.