Silicon powder is widely used in electronics, chemicals, metallurgy, and advanced materials industries, where precision particle classification is essential for ensuring high-quality end products. However, due to its ultra-fine nature and tendency to form agglomerates, traditional screening methods often struggle with mesh clogging, inconsistent separation, and low efficiency.

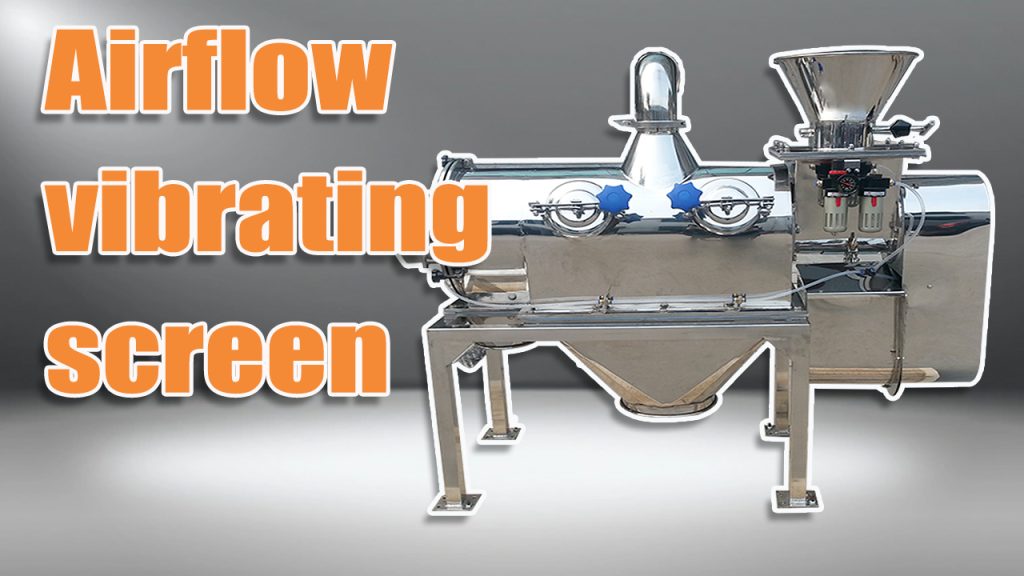

Our Airflow Vibrating Sieve is specifically designed to tackle these challenges, providing a high-speed, reliable, and continuous screening solution for fine and ultra-fine silicon powder. With versatile installation options, advanced airflow technology, and an innovative gas protection system, our equipment ensures long-term stable operation, minimal maintenance, and optimal screening efficiency.

Key Features of Our Airflow Vibrating Sieve for Silicon Powder

1. Single-Unit or Multi-Machine Operation for High Scalability

- Our airflow vibrating sieve can be used as a standalone unit for small-scale production or integrated with multiple machines for large-scale industrial applications.

- This modular design allows businesses to scale up production without compromising screening accuracy.

2. Compatible with Positive & Negative Pressure Airflow Systems

- The airflow vibrating sieve can be easily connected to both positive and negative pressure airflow systems, making it adaptable to different industrial setups.

- This feature ensures efficient dust control, improving workplace safety and maintaining a clean production environment.

3. Continuous Long-Term Operation for Maximum Productivity

- Our airflow vibrating sieve is built for 24/7 continuous operation, ensuring uninterrupted production.

- The machine is designed with high-quality materials and precision engineering, making it stable, safe, and highly reliable for long-term industrial use.

4. Gas Protection System for Reduced Maintenance & Extended Lifespan

- One of the biggest advantages of our airflow vibrating sieve is the gas protection system, which minimizes wear and tear by reducing friction and material buildup inside the machine.

- This protective mechanism significantly reduces maintenance frequency, extends the lifespan of the sieve, and ensures consistent performance over time.

5. High Screening Efficiency & Ultra-Fine Powder Handling

- The combination of airflow-assisted vibration and cyclone technology ensures high-efficiency particle separation without clogging the mesh.

- Even ultra-fine silicon powder flows smoothly through the system, maintaining high throughput and precision classification.

Ideal Applications for Silicon Powder Screening

Our Airflow Vibrating Sieve is widely used in industries that require high-precision ultra-fine particle classification, including:

✔ Electronics & Semiconductor Manufacturing – Ensuring precise silicon powder grading for use in semiconductor production.

✔ Chemical Industry – Screening ultra-fine silicon powders used in coatings, plastics, and chemical formulations.

✔ Metallurgy & Advanced Materials – Separating fine silicon particles for metal alloys and composite materials.

✔ Aerospace & High-Tech Manufacturing – Maintaining ultra-fine powder purity for advanced engineering applications.

Why Choose Our Airflow Vibrating Sieve?

🔹 Single or Multi-Machine Operation – Scalable solutions for both small and large-scale production.

🔹 Positive & Negative Pressure Airflow Compatibility – Ensures flexible integration into different industrial setups.

🔹 24/7 Continuous Operation – Built for long-term, stable, and reliable performance.

🔹 Gas Protection System – Reduces maintenance, extends lifespan, and minimizes downtime.

🔹 Ultra-Fine Powder Screening – Designed specifically for fine and difficult-to-screen materials like silicon powder.

Upgrade Your Silicon Powder Screening Process Today!

If you are looking for a high-efficiency, low-maintenance, and ultra-fine powder screening solution, our Airflow Vibrating Sieve is the perfect choice. With advanced airflow technology, continuous operation capability, and a protective gas system, this machine ensures optimal productivity and long-term reliability for your industrial needs.