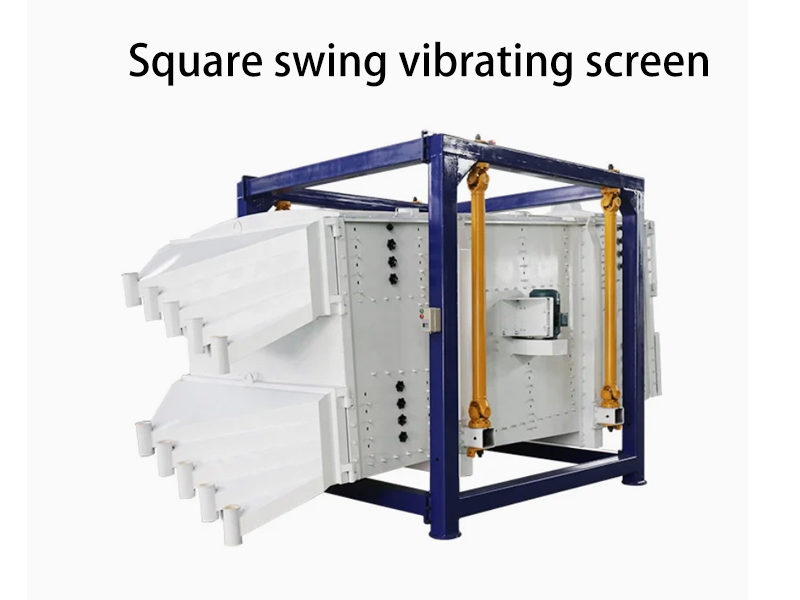

In industries where abrasive materials are handled, achieving precise screening and separation is crucial for maintaining quality and efficiency. Abrasive screening presents unique challenges due to the toughness and harshness of the materials involved. To address these challenges, the square swing screen has emerged as a highly effective solution, providing professional-grade performance and superior separation capabilities.

The Challenge of Abrasive Screening

Abrasive materials, such as sand, minerals, and certain chemicals, are often tough and can cause significant wear and tear on conventional screening equipment. Their high abrasiveness and large particle sizes can quickly damage standard screens, leading to frequent maintenance, increased downtime, and reduced productivity. As a result, industries that rely on these materials need a screening solution that can not only handle the physical demands of abrasive substances but also provide accurate separation and consistent performance.

Why Choose Square Swing Screens for Abrasive Screening?

The square swing screen is specifically designed to meet the demands of abrasive screening by combining advanced technology with a robust structure. Below are some of the key features that make the square swing screen a professional solution for abrasive material screening:

1. Enhanced Durability for Tough Materials

One of the standout advantages of the square swing screen is its durability. The materials used in the construction of these screens are designed to withstand the harsh conditions that come with screening abrasive substances. The reinforced structure of the square swing screen ensures that it can handle the physical stress of abrasive materials without suffering from excessive wear or damage.

This increased durability reduces the need for frequent repairs and maintenance, which in turn lowers the overall operational costs for businesses. With this screen, you can count on long-lasting performance, even when dealing with the toughest abrasive materials.

2. Superior Screening Precision

A key concern when handling abrasives is ensuring that the materials are screened and graded with high precision. The square swing screen excels in this area due to its unique swing motion, which mimics the natural action of hand sieving. This motion ensures that materials are evenly distributed across the entire screen surface, resulting in accurate separation.

Whether the goal is to separate fine particles from coarse ones or to remove impurities from a mixture, the square swing screen offers precision grading that helps achieve the desired material quality. This feature is essential in industries where the consistency and quality of the end product are paramount.

3. Increased Throughput and Efficiency

Another benefit of the square swing screen is its ability to handle large volumes of material efficiently. Thanks to its larger screening surface and optimal design, the square swing screen allows for higher throughput compared to traditional screening equipment. This increased capacity helps businesses meet production demands without sacrificing the quality of the screened material.

The swinging action ensures that materials flow evenly across the screen, reducing the risk of clogging or buildup that can slow down the screening process. As a result, businesses can achieve faster processing times, improve operational efficiency, and meet tight production deadlines.

4. Reduced Maintenance and Downtime

The square swing screen is designed with ease of maintenance in mind. Its simple construction and easy-to-clean design allow for quick and effective maintenance, minimizing the time and effort required for upkeep. In industries that deal with abrasives, where equipment wear is a concern, the low maintenance nature of the square swing screen helps to keep operations running smoothly with less frequent interruptions.

Moreover, the durable components and resistant materials reduce the need for costly repairs, meaning less downtime and more consistent production. This results in improved productivity and reduced operational costs.

5. Versatility in Application

The square swing screen is a versatile solution capable of screening a wide range of abrasive materials. Whether you're working with sand, gravel, minerals, or metals, the square swing screen can efficiently separate and grade these materials according to their size and quality. This versatility makes it an ideal solution for industries such as mining, construction, metal processing, and chemical manufacturing.

Its adaptability ensures that businesses can rely on the same equipment for multiple applications, further enhancing operational efficiency and reducing the need for different types of screening machines.