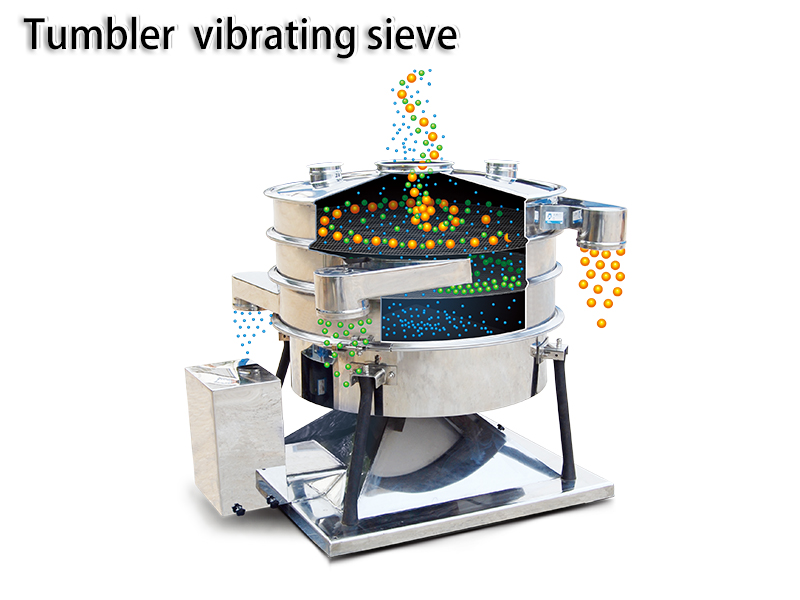

In industries that require precise material classification and high throughput, the Tumbler Vibrating Sieve is an ideal solution. Unlike conventional high-frequency vibrating screens, this advanced sieve mimics the natural hand-sieving motion, providing gentle yet effective material separation. With its ability to handle multiple particle sizes and minimize material degradation, the Tumbler Vibrating Sieve is perfect for processing dry, low-density, and abrasive materials while extending the lifespan of the screening mesh.

High-Capacity Multi-Layer Screening

One of the most impressive features of the Tumbler Vibrating Sieve is its large screening capacity and ability to classify multiple particle sizes in a single operation:

✔ Supports up to 6 particle size classifications – enabling precise separation of fine and coarse materials.

✔ Customizable sieve diameters – ranging from 600mm (24 inches) to 2600mm (104 inches) to accommodate different production scales.

✔ Multi-layer screening capability –

- Smaller models can be equipped with up to 4 screening layers.

- Larger models can feature 5 layers, achieving 5 to 6 classification levels in one operation.

✔ Enhanced single-grade processing – Our advanced technology doubles or even triples the capacity for single-grade material classification within the same sieve.

This versatility ensures optimal efficiency and flexibility, making it ideal for industries requiring high precision and large-scale processing.

Simulating the Natural Hand-Sieving Motion

The working principle of the Tumbler Vibrating Sieve is based on the mechanical simulation of human hand sieving. Unlike aggressive vibratory screens that use high-speed linear or circular motion, the Tumbler Sieve uses gentle acceleration and low-speed operation, ensuring:

✔ Smooth material movement across the screen surface, reducing stress on particles.

✔ Consistent rolling motion, improving separation efficiency.

✔ Lower impact force, protecting fragile materials from breakage.

This makes the Tumbler Vibrating Sieve an ideal choice for delicate, brittle, or lightweight materials that require careful handling during classification.

Optimized Performance for Dry, Low-Density, and Abrasive Materials

The Tumbler Vibrating Sieve is particularly effective for dry and low-density materials, as its rolling motion prevents particles from becoming airborne or accumulating unevenly. Additionally, the low-impact screening mechanism offers:

✔ Reduced wear and tear on the sieve mesh – especially crucial when handling abrasive materials.

✔ Extended equipment lifespan, minimizing maintenance costs.

✔ Consistent particle distribution, ensuring uniform separation results.

This feature makes it highly suitable for applications such as:

- Food Industry – Screening dry food ingredients, starch, milk powder, and coffee granules.

- Pharmaceutical Industry – Precise classification of powdered medicines and herbal extracts.

- Chemical Industry – Separating fine chemical powders with high precision.

- Metal Powders – Handling fine metallic and alloy particles with reduced mesh wear.

Key Benefits of the Tumbler Vibrating Sieve

✅ Handles up to 6 particle classifications simultaneously, improving efficiency.

✅ Large screening diameter (600mm - 2600mm) for increased capacity.

✅ Multi-layer screening (up to 5 layers) for precise separation.

✅ Gentle rolling motion prevents material damage and reduces mesh wear.

✅ Ideal for dry, low-density, and abrasive materials.

✅ Low-speed operation extends equipment lifespan and reduces maintenance.