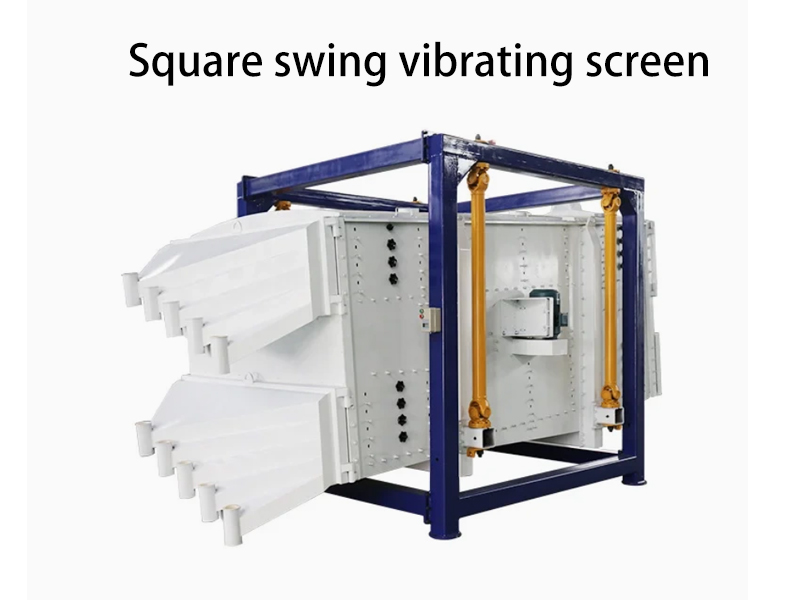

High-Performance Grading and Screening of Perlite with the FYBS-1536 Square Swing Vibrating Screen

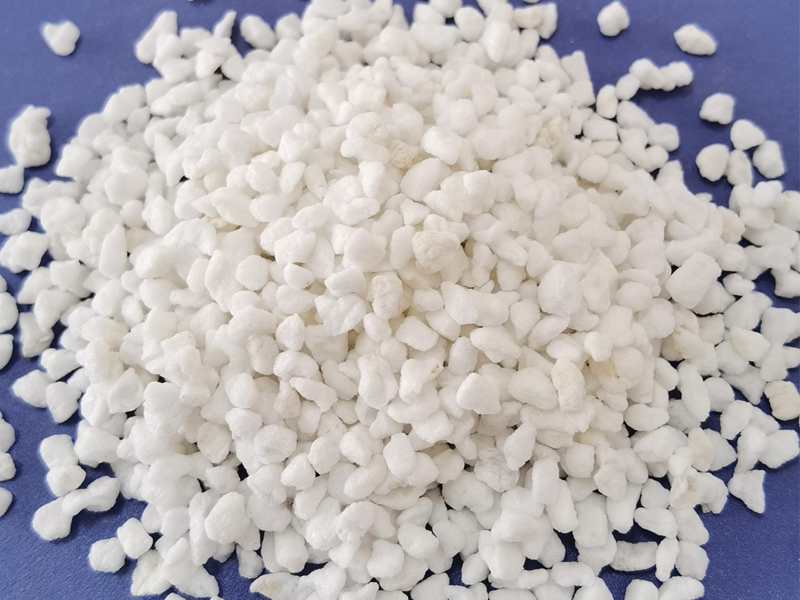

In industries such as construction, agriculture, and insulation, perlite is a highly valued material known for its light weight, insulating properties, and versatility. To ensure perlite meets the required size specifications for different applications, it must be efficiently graded and screened. The FYBS-1536 Square Swing Vibrating Screen is the perfect solution for high-volume perlite screening, offering 30t/h output capacity, precision, and reliability. This advanced machine ensures the efficient separation of perlite particles, making it ideal for perlite processing plants, construction material manufacturers, and more.

1. FYBS-1536 Square Swing Vibrating Screen

The FYBS-1536 Square Swing Vibrating Screen is a powerful, high-capacity screening machine specifically designed for grading and separating bulk materials, including perlite. With a throughput capacity of 30t/h, it is capable of handling large quantities of material, ensuring high efficiency and uniformity in the final product. This machine uses a square swing motion that mimics hand sieving, providing gentle yet effective separation of particles based on their size.

2. Key Features and Advantages

(1) High Capacity and Efficiency

With an impressive output capacity of 30t/h, the Gyratory Sifter is designed for large-scale industrial applications. It efficiently processes high volumes of perlite, making it an ideal solution for large processing plants. Its high throughput ensures continuous, uninterrupted production, which is essential for meeting the demands of industries relying on large quantities of graded perlite.

(2) Precise Grading and Separation

The unique swing motion of the FYBS-1536 ensures that particles are screened and separated effectively according to size. This motion creates a "horizontal" screening effect, which prevents fine particles from blocking the mesh, providing accurate classification of perlite into different grades. The result is a high-quality final product with uniform particle sizes, suitable for use in various applications such as lightweight concrete, horticulture, and insulation materials.

(3) Versatile and Customizable for Different Applications

The FYBS-1536 is highly adaptable and can be configured with multiple screen decks to cater to the specific needs of perlite grading. Whether separating coarse perlite from fine or medium-sized particles, this machine can be customized to meet the requirements of different applications. The screen's adjustable amplitude and frequency allow operators to fine-tune the separation process to achieve the desired grading accuracy.

(4) Durability and Long Service Life

Built from high-quality carbon steel, the FYBS-1536 is engineered to withstand the rigors of continuous, high-capacity operations. Its robust construction ensures that it can handle even the most challenging materials, including abrasive substances like perlite, without compromising performance. This durability translates to a longer service life and fewer maintenance needs, reducing operational costs over time.

(5) Low Maintenance and Easy to Operate

The FYBS-1536 is designed for ease of use, with simple controls and a user-friendly interface. The machine requires minimal maintenance due to its rugged design and efficient operation. Regular inspections and occasional cleaning are all that is typically needed, keeping downtime to a minimum and ensuring that production runs smoothly.

(6) Energy Efficient

The Gyratory Sifter operates with high energy efficiency, ensuring optimal performance without excessive energy consumption. This makes it an environmentally friendly choice for perlite processing plants that are looking to reduce operational costs and minimize their carbon footprint.

3. Applications of the FYBS-1536 Square Swing Vibrating Screen

The FYBS-1536 Gyratory Sifter is particularly effective for grading and screening perlite, where accurate particle separation is crucial. Some of the key applications include:

- Perlite Grading: Separating coarse, medium, and fine perlite particles for different uses such as horticultural applications, insulation, and construction materials.

- Lightweight Concrete Production: Ensuring that perlite is correctly graded for use in the production of lightweight concrete, where particle size consistency is essential.

- Agricultural and Horticultural Use: Screening perlite for use as a soil conditioner or growth medium, where uniform particle size promotes optimal plant growth and water retention.

- Insulation Materials: Grading perlite for use in the manufacture of insulation products, ensuring the material meets specific size requirements for thermal efficiency.

This Gyratory Sifter provides accurate separation and consistent grading of perlite, ensuring that the material meets the desired specifications for use in various industries.

4. Why Choose the FYBS-1536 Square Swing Vibrating Screen?

For businesses in the perlite processing industry, the Gyratory Sifter offers numerous advantages:

- High Output: With an impressive throughput capacity of 30t/h, it can efficiently process large quantities of perlite, meeting the demands of high-volume production lines.

- Precise Particle Separation: The machine's swing motion ensures effective separation, providing uniform particle size distribution and consistent product quality.

- Durable Construction: Built from high-quality carbon steel, the screen is durable and capable of withstanding tough materials, reducing the need for frequent maintenance.

- Versatile Applications: The customizable screen configuration allows it to be adapted to various perlite grading and separation needs across industries such as construction, horticulture, and insulation.

- Low Operational Costs: The energy-efficient design helps to reduce operational costs, while its low-maintenance nature keeps overall expenses down.

- Easy Operation and Maintenance: The machine is user-friendly, with simple controls and minimal maintenance requirements, ensuring a smooth and reliable operation.